Saturday, September 27, 2025🕚 11:00 AM – 6:00 PM📍 59 Orchard Street, Lower East Side, NYC If you’re a fan of vintage denim, creative customization, and the culture surrounding rugged American workwear, Denim Edition might be the best denim show you’ll attend

Read More →

Jeans and pants are a part of our everyday lives, and there’s more to them than just the fabric. Have you ever thought about the seams? They play a big role in how your jeans and pants look, feel, and last.

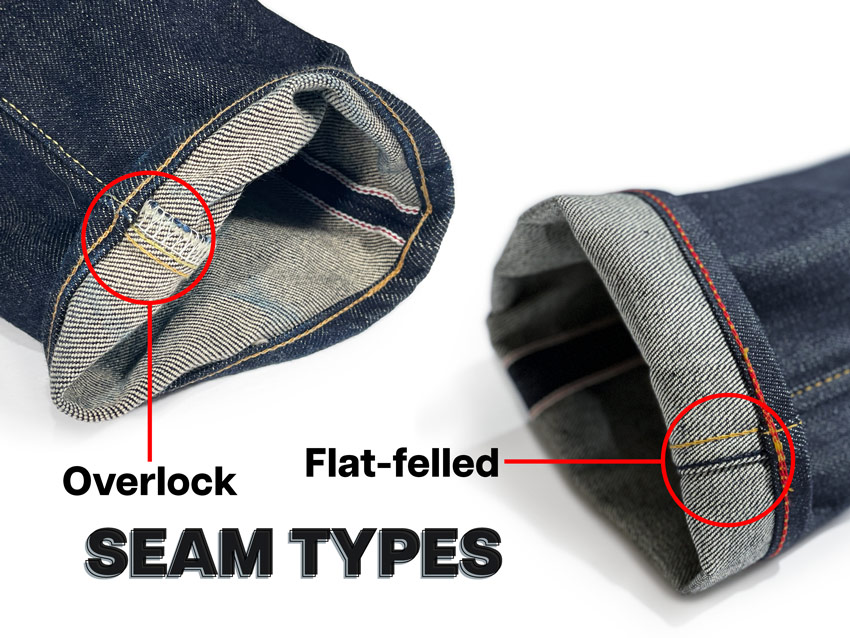

Excluding tailored clothing which is generally a single lockstitch with merrow stitching or binding over the edges, the two main kinds of seams in jeans and similarly constructed pants are flat-felled and overlocked seams.

If you’re thinking about tailoring your jeans or pants (especially tapering) or just want to know more about fashion, it’s good to understand these seams. Why? Because each seam type comes with its own set of benefits and challenges that can significantly affect the alteration process, durability, and aesthetics.

Flat-felled vs. Overlocked seams

Flat-felled seams are the most common type of inseam construction on jeans and similarly constructed pants. They are created by folding the raw edges of the fabric over, and on themselves, then stitching them together. This creates a strong and durable seam that is also very flat and neat. These seams are celebrated for their durability, fray resistance, clean finish, and aesthetic value. Flat-felled seams are often used on high-quality jeans in the light-to-midweight fabric range but can be a problem with heavyweight or thick fabrics because of the multiple layers of folded fabrics required to sew through where seams meet and the fabric’s weight.

When it comes to sewing through multiple seams, manufacturers of heavyweight denim will use flat-felled seams at the seat, even though they must sew through 12 layers of fabric where the yoke and center seat seams meet, and avoid the flat-felled seam on the inseam, where 8 layers of fabric must be sewn through in the crotch, for several reasons.

First, in the seat area of jeans and similarly constructed pants, the flat-felled’s low profile, smoothness, and visual aesthetic have more value than an overlocked seam. Second, because of the shorter distance regarding sewing, errors can be more quickly corrected compared to the long distance at the inseam.

Some brands, such as Bravestar and a few others, will take on the massive challenge of producing heavyweight jeans with flat-felled inseams. Sewing flat-felled inseams of heavy jeans during tapering is tough in our experience, not because of the fabric’s thickness, but due to the weight and gravity pulling on the jeans while they hang under the off-the-arm sewing machine. The weight exerts a continual tug on the fabric, which the sewer is attempting to hold upward into the folder, which causes the fabric edges to turn over, to create flat-felled seams. Shorter sewing distances, such as the rear yoke and center seat seams, are not a problem. Longer sewing distances, such as the inseam, have three to four times the weight and force pulling the fabric down and out of the folder. As a result, every time the sewer adjusts their hand position while sewing, the fabric slips down, or lower in the folder, causing sewing problems. This is most certainly the most significant explanation for why factories prefer to produce heavyweight jeans with overlock inseams.

Overlock seams, also known as serged seams, are another common type of inseam construction. These are generally used on the insides of the garment. Overlock seams are created by an overlock machine, which stitches the seam, trims the seam allowance, and encases the edge of the fabric with thread, all in one step.

The overlocked seam is more valued at the inseam on heavyweight jeans because it’s easier to sew. Also, it does not create as much bulk where the seams meet in the crotch, where there is lots of movement, unlike the yoke area of the seat, which sits flat. Lastly, the more unsightly appearance of the overlock seam is not visible on the inseam unless the jeans are turned up at the hem.

While not as durable or aesthetically pleasing as flat-felled seams, overlock seams are quicker and more economical to produce. They also provide adequate fray resistance, which is particularly important on the raw edges of denim.

The Importance of seam type in Tapering Jeans and Pants

What does this have to do with getting your pants and jeans tapered? To begin with, the type of seam influences the method and difficulty of making an alteration. The vast majority of tailors will taper jeans and pants from the outseam to avoid the inseam because of a lack of equipment, knowledge, or both. This is not an option with selvedge clothing since it would damage the selvedge. Unless flared, or garments designed for curvy bodies, the shape of jeans and pants legs is typically drafted in the inseam, leaving the outseams mostly straight up to the hips. As a result, modifications should also be made to the inseam.

Tailoring flat-felled seams requires a feed-off-the-arm sewing machine to be done correctly, and in order to maintain the original construction. It also requires skill and knowledge of the construction techniques used on mass-produced read-to-wear garments, which often have very different rules than tailored clothing.

Overlock seams, on the other hand, are easier and faster to alter. An overlock machine, which is one of the more common types of sewing machines available in many types of tailoring establishments, can be used to cut and re-sew the seam. Most tailors will struggle with how to handle the top stitch that is sewn on top of overlocked seams. Without an off-the-arm machine, it’s impossible to sew a fresh top stitch from hem to hem in a single pass, without taking the garment apart. Because they can only sew so far up the leg, heading upward towards the crotch, they must either link a new top stitch to the previous one. Alternatively, they can open the outseams all the way to the hips in order to fit the jeans or pants through a flatbed machine, sewing around the inseam, in a single pass.

In Summary

Choosing to taper your jeans can give them a fresh lease of life, adapting them to changing trends or personal style preferences. But before you take them to a tailor, examine the inseam construction. Knowing whether you’re dealing with a flat-felled or overlocked seam will help you understand the complexity of the task and manage your expectations regarding cost, time, and final appearance. This way, you’ll ensure you’re making an informed decision about tailoring, helping your favorite denim remain a staple in your wardrobe for years to come.

You might be interested in

Most people simply don’t realize that tailoring jeans or knitwear is a specialized service. It’s not something every tailor does

You may have tried learning through YouTube or social media videos—but when you’re serious about mastering a craft, you quickly

When it comes to buying jeans—especially online—getting the right inseam measurement is crucial for a proper fit. Whether you’re checking

Got a twisted leg on your jeans? If one leg seam always seems to drift to the front or back,

Summary

Jeans hemming is the process of shortening the leg or inseam length of a pair of jeans by removing some of the fabric from the bottom.

These photographs demonstrate the before and after effects of hemming alterations made by Williamsburg Garment Company to shorten the inseam of jeans to demonstrate “what jeans hemming is.” The top photograph features a pair of Pure Blue Japan jeans. It displays the altered inseam and leg openings as well as the portions of the hem that was removed.

The below image displays a pair of raw denim jeans with their original hem and full inseam length. A chalk line on the jeans marks the hemming cut line, which also includes a 1/2-inch double fold (1-inch).

The majority of jeans are sewn with chain-stitched hemming. The average hem measures roughly 1/2 inch tall. A tailor or seamstress double folds the raw edge after cutting to the hem (leg opening). Since each fold measures approximately 1/2 inch, the inseam length must be increased by 1 inch to reach the desired length.

To see what we mean by double folding, and the process of hemming in action. Watch our video “Chain Stitch Hemming in 87 Seconds.”

Chain Stitch Hemming in 87 Seconds

You might be interested in

Most people simply don’t realize that tailoring jeans or knitwear is a specialized service. It’s not something every tailor does

You may have tried learning through YouTube or social media videos—but when you’re serious about mastering a craft, you quickly

If you’ve ever typed how to take in the waist of jeans into Google, you’ve probably seen a lot of

The first brand in our new lineup was TCB Jeans, a company out of Kojima, Japan that builds its reputation

So you splurged on that vintage-looking pair of Gap 1969 jeans. They are everything you were looking for, but about 4-to-5-inches too long. Now what? You don’t want to wear them rolled with a huge cuff – or even have them stacking over your shoes. You want to make them one of your go-to jeans, so you need them to fit right. Here’s how you can make that happen: With fast professional chainstitch denim hemming service that’s available from any city or town in the USA! We make our alterations services simple and both affordable and easy to execute. Read on to learn how we can help you achieve the perfect fit:

What is a Chainstitch Hem?

A chainstitch hem is a technique used in most jeans. It’s a fairly common and durable stitch that is found on most jeans. As seen on the above pair of Gap 1969 jeans, you’ll want to ensure when shortening your inseam, the jeans have the same style of sewing as the original store-bought jeans. That’s with chain stitching and thick, heavy threads. Both are not options not usually found at local tailors, cleaners, and even department stores or a brand’s in-store alterations services. Read more on chainstitch hemming on our blog.

How to order Hemming from us

We receive and ship altered jeans, pants, and shirts from all over the USA. Sometimes, those seeking the very best denim services will ship us garments from other countries. We offer low-cost 2-way shipping options, so you can ship 1 or multiple items in an order for the same low price. With 2-way shipping, we email you a shipping within a few hours of placing your order, or the next morning when ordering after business hours.

Additional Rush Alterations Options to Consider

We offer RUSH and STANDARD SERVICE. The fastest is Same-Day while you wait. The next fastest is 1-Day Service. Our regular service takes about 5-to-7 days. Pricing for all services is listed on the ordering page.

The Catch-22 of Denim Hemming

Unfortunately, there are DIY techniques and non-professional denim tailors who offer what’s called an Original Hem alteration. They say you can retain the original pre-washed edge on the leg opening, but they don’t tell how bad your jeans will look on the inside or how you will lose the flexibility of the hem.

Final Words

Original hems are a bad idea. Don’t let anyone talk you into this style of alteration. We get lots of jeans sent to us with requests to undo this alteration and re-hem the jeans correctly with chain stitching.

The pre-washed edge on the leg opening, as seen on the section cut from Gap 1969 jeans comes back in time with washing and wearing. If you want to speed up the process, you can rough up the hem with sandpaper, a sharp blade, or an electric grinder for the shredded look. For fast fading, wet and wrinkle the hem, then rub in a small amount of bleach on the high points, and dip the hem in cold water to halt the fading. Machine wash the jeans after.

You might be interested in

Most people simply don’t realize that tailoring jeans or knitwear is a specialized service. It’s not something every tailor does

You may have tried learning through YouTube or social media videos—but when you’re serious about mastering a craft, you quickly

If you’ve ever typed how to take in the waist of jeans into Google, you’ve probably seen a lot of

The first brand in our new lineup was TCB Jeans, a company out of Kojima, Japan that builds its reputation

We fix a lot of professional tailor shops and DIY home sewing machine hemming jobs. People learn the hard way that home sewing machines aren’t up to standard when working with denim and then send jeans to us for re-hemming. The thick seamlines are just too much for most domestic machines, so we often find thin broken needles stuck inside of hems.

Others discover that the difference between the quality of denim alterations from a suit tailor or local cleaners, and us is like night and day. That’s because the heavyweight fabric requires specialized machines and the workmanship required for denim is worlds apart from suits, fine trousers, dresses, and style of garments commonly worked on at most tailoring shops.

Hems are commonly sewn with chain stitching at jeans factories. Most professional tailors will try to hem jeans on single-needle lockstitch machines, but they often can’t handle the thick fabric or seams. Again, home sewing machines aren’t nearly capable.

When it comes to stitching sizes, professional tailors will use threads that are a little heavier than the small thread sizes which must be used in domestic machines. But still, they usually don’t stock the thicker thread sizes commonly used with denim. The difference is plain to see when it comes to jeans- have them professionally altered by a denim specialist.

You might be interested in

Most people simply don’t realize that tailoring jeans or knitwear is a specialized service. It’s not something every tailor does

You may have tried learning through YouTube or social media videos—but when you’re serious about mastering a craft, you quickly

If you’ve ever typed how to take in the waist of jeans into Google, you’ve probably seen a lot of

The first brand in our new lineup was TCB Jeans, a company out of Kojima, Japan that builds its reputation

We analyze our Slim Standard Grand Street jeans after washing and wearing them to explore how the fit of raw denim jeans can vary over time. The style before the wash feels starchy and crisp. It was produced in a mid-weight, 11.5-ounce, American-made Cone Denim White Oak non-selvedge denim.

We do a lot of denim alterations, not just on our jeans but also on those from numerous other brands. The bottom line is that we get to see a lot of denim, which is a plus. They arrive with us new, slightly used, well-broken-in, or terribly damaged and devastated.

In the case of Williamsburg jeans, this enables us to contrast various levels of our used denim with those of the same style that are brand-new, off-the-rack. These jeans were brought in for button repair work. It was a fantastic pair to study because they hadn’t had any hemming or other adjustments done that would have made them out of the original specifications.

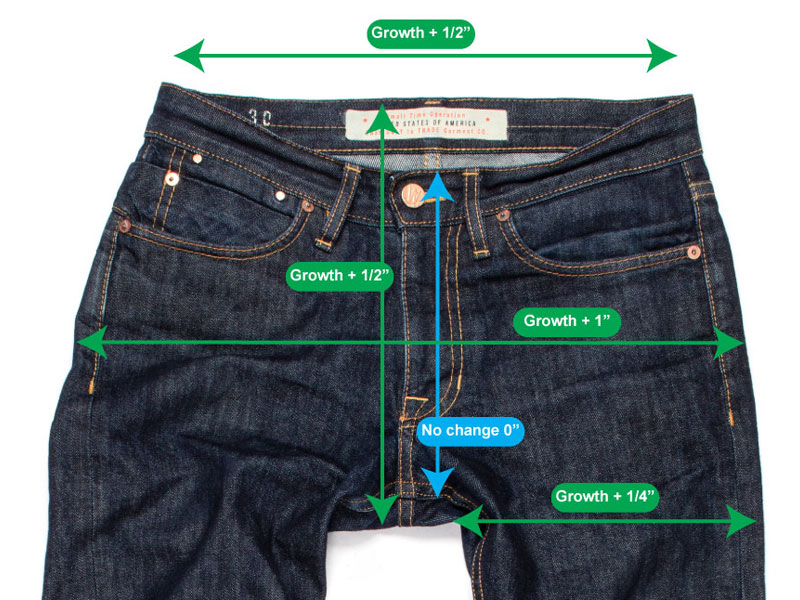

The measurements between the new and the older pairs of jeans are shown here. Because of the yarn colors, fabric texture, softness, and lack of oil in the fabric, we know this pair has been washed at some point throughout its history, even if we didn’t inquire. The signs of stretching are prevalent in locations that experience typical stress, so we know the jeans were worn after being washed.

You should be aware that when it comes to raw denim, each fabric that makes up the product may have varying rates of shrinkage or growth. This is true whether you own a pair of raw jeans from another manufacturer or even a different model of Williamsburg jeans. When soaked in water, some denim actually expands in one direction rather than contracting. Others may have little or significant stretching.

Finally, size is important. In the same fabric, a 1/4 inch increase on size 30 jeans could translate to a 3/8 to 1/2 inch increase on size 40 jeans. This is due to the fact that larger size changes are being felt over greater distances.

For more information, or to review spec changes in other styles, check out past articles.

This is no fabrication. A few weeks ago, I woke from a nightmare having dreamt Cone Denim, our main supplier of denim fabric, closed its doors and people were buying up everything down to bare shelves at our retail store. However, that was just a dream. Our denim supplier has been producing quality denim for over 125 years and has the oldest denim mill in the United States of America. A shut-down of its famous White Oak Plant which produces its U.S.-made denim and is the last mill standing that makes selvage denim in the USA is very unlikely. Right?

The day before writing this, I saw a spike in sales and I thought, maybe it was due to the results of the articles being written, inspired by our press release a few days earlier. Later that night after work, my wife asked if I heard the news about Cone Mills White Oak Plant closing. I thought, clearly she was mistaken and I went online to check it out.

If you are not familiar with Cone Denim Mills, they have been America’s leading supplier of high-quality denim fabrics to apparel brands since 1891. Nearly all of the most popular and successful small to mid-sized domestic jeans makers in the United States rely on Cone Denim as a key supplier. At Williamsburg Garment Company, about 90% of the denim we use is American-made Cone Denim. I stress the point that we use American-made denim because Cone branded denim is also manufactured in mills located in China and Mexico. I learned from dealing with import complications and extra costs, to walk into the Cone showroom or tradeshow booth and stress, only show me the new American-made fabrics.

After doing some research and contacting Cone Denim, I was shocked to learn that Cone was indeed planning to close its 112-year-old White Oak Plant in Greensboro, North Carolina, which produces all of the company’s American-made denim and employs nearly 200 people. Initially, I hoped this was one of those times when an announcement is made for the closing or end of something very dear to a fan group, like Jay-Z’s Black Album. Closing announcements can sometimes be used to ignite sales, meanwhile re-organizing and re-opening is really what is planned.

I hoped and suspected something would be announced later like, deciding to downsize the White Oak Plant or move the production to a new smaller more optimized manufacturing facility. However, after remembering International Textile Group, Cone Denim’s parent company was acquired via a Public-to-Private transaction in October 2016 by the investment firm Platinum Equity, I feared the worst, knowing the thinking behind money people. When it’s strictly about turning a profit, closing the least profitable parts of an operation, like U.S. manufacturing, to focus on the more profitable parts, like foreign manufacturing, is normal thinking.

This seems to be what may be happening as a rep at Cone Denim has informed me, “ultimately there will no longer be any denim (wide and selvage) produced in the USA after December 31, 2017. All denim operations will be focused out of Mexico and China.”

Are the days of buying American-made jeans manufactured in denim fabric made in the USA coming to an end?

I sat in the park later that day teary-eyed in unbelief. Thinking this can’t be happening. Will 2018 be the last year to get true American-made jeans manufactured with denim made in the USA? Will the U.S.-made denim supply run out? Will American-made jeans be defined from that point on as jeans sewn in the USA of Mexican, Japanese or Chinese-produced fabrics?

Some 100 years plus of heritage could be wiped out by inventors looking to make profits with one-dimensional thinking. I believe it should be as simple as optimizing the business to succeed in the way business is done today. Not to look on the surface and say this is profitable and this is not, cut out the non-and least profitable. With something this important to the country, I believe you have to find a solution to make it work. It boils down to the old saying, where there’s a will, there’s a way. Too often, money-types come in and take the easy route – stripe everything down, repackage and sell it off for profit, often destroying a brand on their way out.

In this case, they would be ignoring years of heritage and stripping the growing economy of small to mid-sized brands like ours that rely on Cone White Oak denim. We do business in today’s economy. Small-batch, online, direct-to-consumer businesses that focus on making a better product. We helped to ignite the comeback of American-made products after the downturn in the economy and after bigger brands move production overseas for higher profits.

I love Cone Denim. However, I’ve always thought they were underachieving as a brand. Often, big companies are too slow to modernize in changing times or get stuck in a do-the-same-thing we’ve always done strategy. Today, more than ever, you have to think outside the box and clearly define your strengths and weaknesses. Which does not mean cutting off your weaknesses to focus on your strengths. It means being clearly aware of what they are, so you can make both work for you.

Bottom line, any type of business where deep American tradition gives it great value around the world, which produces some of the best products in the world, backed by more than 100 years of heritage and has a highly respected brand name, should be profitable. If a business that has been based in the U.S. for over a century can’t use those things to be successful. The size of a plant and order volumes may not be the problem. Looking into taking advantage of the company’s strengths could help.

Most hard-core denim heads and industry folk are familiar with Cone’s brand. This is why, after the announcement of the plant closing, it took me a day to hear about it and we are one of the company’s customers and players in the denim industry.

In my opinion, this story is so big it should be national news and running in CNN’s hourly rotation with the headline “Is this the end of American-made Denim?” For this to be a top story at CNN, MSNBC, Fox, or the three major networks, does someone have to mention the connection with Wilbur L. Ross, Commerce Secretary of Trump’s MAGA billionaire posse?

To complete the merger transaction, Platinum Equity acquired all of the debt and equity securities of ITG, previously owned by entities managed by W.L. Ross & Co. LLC and its affiliates. Not saying that the Commerce Secretary is at fault for the actions of who took over, but anytime an American Institution trades hands, you should have faith that the new tenant is going to take care of the place. And, if President Trump is truly trying to help American manufacturing, he and Mr. Ross need to get some billionaires together that will put this thing back in the hands of those who understand the importance of its American heritage and fix it.

You might be interested in

You may have tried learning through YouTube or social media videos—but when you’re serious about mastering a craft, you quickly

The first brand in our new lineup was TCB Jeans, a company out of Kojima, Japan that builds its reputation

The leg opening measurement is a critical factor in how your jeans fit over your shoes and shape your overall

Washing raw denim has long been a topic of debate. Some purists believe in waiting as long as possible, while