When it comes to hemming pants, maintaining the original look is key. Many tailors use what’s known as an “original hem alteration,” where they cut off the hem and reattach it with an added seam. But let’s be honest—that’s a poor man’s

Read More →

This video is a classic. Back in 2018, before we moved into our current location at 67 West Street in Greenpoint, Brooklyn, while working out of the back room inside Brooklyn Denim Co. in Williamsburg, Brooklyn, our intern Emoni Sheldon and I recorded this video to explain how to taper jeans professionally. With the plethora of DIY hack videos out there, I thought it was crucial to show the proper method. It’s been a hit ever since.

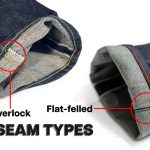

We’ve promised an updated, more detailed version is coming, but we’re always under time pressure to get customers’ jeans in and out the door quickly, so we rarely find time for social media posts or other instructional videos—though we’re looking to change that. This video demonstrates our process for tapering jeans with flat-felled inseams. There’s also a faster, simpler process for tapering jeans with overlocked inseam construction, and we promise to record it soon.

Since we recorded this video, we’ve perfected our process, tapering thousands of jeans from a multitude of brands, and we’ve learned what makes each brand different along with their trademark details and construction.

For now, this is still the best video out there if you want to see how it should be done correctly. Everything else is a workaround hack for doing it yourself on sewing machines that are not built for the task.

You might be interested in

When it comes to hemming pants, maintaining the original look is key. Many tailors use what’s known as an “original

When searching for a denim expert to work on your treasured jeans, the closest option may not be the best

Most jeans and pants use these inseam constructions. Read this before tailoring jeans or pants.

This video, which we posted on Instagram and TikTok, walks you quickly through our chain stitch hemming procedure.

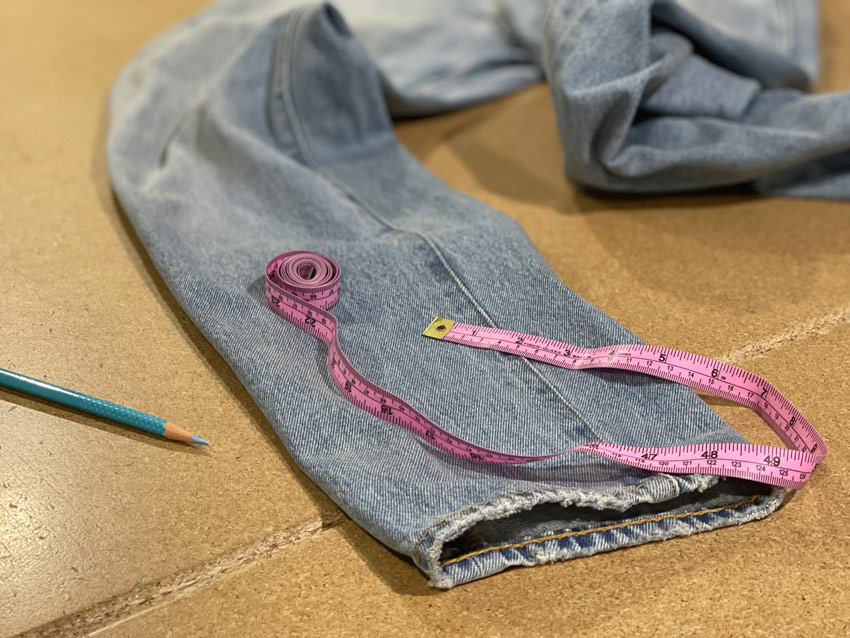

The goal of this tutorial video is to walk you through the complex process of determining the inseam of twisted-leg jeans. In contrast to measuring the inseam on a pair of typical jeans or pants, dealing with twisted legs adds an additional level of complication. When the legs of the jeans wrap around to the opposite side, the dilemma of whether to follow the inseam line arises.

The short answer is no. The key is to follow the natural shape of the jeans as though there were no twist. In this video, we show you step-by-step how to do this.

In addition, we explore some of the frequent mistakes that tailors and clients requesting hemming alterations make while shortening the inseam. This guide will educate you on why using a general request like “take off 2 inches” while asking for a hemming service may not be the best choice. Similar to this, we show how this approach can result in mistakes when shortening jeans for tailors who often align the hems of jeans before simply cutting them. Have a look at our video to enhance your understanding and skills with denim alterations.

You might be interested in

When it comes to hemming pants, maintaining the original look is key. Many tailors use what’s known as an “original

When searching for a denim expert to work on your treasured jeans, the closest option may not be the best

TCB Jeans crafts history into every stitch, reviving iconic denim like the 1966 Levi’s 501 and the 1955 Levi’s 701

Nick English from Stridewise visited our studio at 67 West Street to expertly tailor his jeans at the waist. Watch

In this brief social media video, we show how to hem jeans professionally, just like it’s actually done at denim factories. In our video, there is no need for work-around-sewing-techniques, which leave bulky seamlines over the hem or ragged fabric on the reverse side, which prevents cuffing or rolling the hem. We love denim at Williamsburg Garment Company and hemming jeans the right way is important to us.

Even the heaviest denim is no problem for our beast of a sewing machine, a customized Union Special 56300 that bores through multiple layers of folds and seams. Here, denim designer Maurice Malone demonstrates chain stitch hemming a pair of jeans in our Instagram and TikTok video. Make sure to stay tuned and follow us for more.

You might be interested in

When it comes to hemming pants, maintaining the original look is key. Many tailors use what’s known as an “original

With the plethora of DIY hack videos out there, I thought it was crucial to show the proper method.

When searching for a denim expert to work on your treasured jeans, the closest option may not be the best

How to measure the inseam of twisted-leg jeans is made clear in our video lesson. Learn how to handle this

“Can you tailor denim jackets?” is a frequently asked question at Williamsburg Garment Company. Our answer, as with all denim products, is, of course, yes, but jackets and shirts are more complicated. They have armholes and shoulder widths that correspond to the width of the body. When you narrow the body width evenly, the armhole shrinks and the armpit curve is negatively affected. At the same time, the shoulder width remains constant, resulting in wide shoulders compared to the body width. The only way to avoid this is to remove the sleeves and, if possible, draft new armholes and sleeve shapes. Otherwise, you can leave the armhole alone and narrow the body unevenly from the chest/armholes down.

Nothing about modifying denim jackets is simple or easy. The body width is linked to the armhole and shoulders, whereas the sleeve length is linked to the button placket length and/or the armhole.

Can you tailor denim jackets on a home sewing machine?

When it comes to DIY denim jacket alterations, the short answer is that you can do it, but it is not recommended. If you’ve done any research on the subject, you’ve probably discovered that all of the videos and advice you’ve seen have had poor results on cheaply made garments.

Flat-felled seams on the sides, shoulders, and sleeves distinguish traditional jean jackets. This design eliminates the option of doing high-quality alterations on home sewing machines, at your local dry cleaners, or at the best, most reputable tailoring shops. Most denim alterations specialists lack the factory equipment (a Feed-off-the-Arm 3-Needle or Double Chainstitch Industrial Sewing Machine) to duplicate the double-needle flat-felled seam with chain stitching and must come up with an improvised method to sew them.

Most denim jackets and jeans are produced with fabric that is too thick for home machines. To tailor denim on a home sewing machine, you would need to avoid thick seams or deal with really thin, lightweight denim fabrics.

Thread size is also an issue with DIY and most tailoring shops. Denim is typically sewn with thicker thread sizes than most other garments, which contributes to its distinctively sturdy appearance. Home machines are not designed to handle the needle sizes required for thick threads. They also lack the ability to puncture through layers of denim using wide-diameter needles with large eye holes. Thin thread sizes and short stitch lengths are two of the reasons why denim does not look like denim when it is not sewn with the proper threads.

How altering a jean jacket professionally is done

The owner of this heavyweight Oni Denim jacket adored it, however, he had a small frame and required the chest and arms reduced. Here are the steps we used to customize his denim jacket:

1. Chain-stitched flat-felled seams close the sides and sleeves of traditional jean jackets. Because the band at the bottom is chain stitched to the jacket, our first step was to remove the chain stitching connecting the waistband to the body, just enough to remove excess fabric and resew the seams closed.

2. Following that, we split the waistband and removed the chain stitching that held the flat-felled seams together from the waistband to about 6 inches from the cuff seam. After narrowing the excess fabric around the bicep, just past the elbow, we could neatly flow into the sleeve.

3. We press flat the flat-felled seam folds in order to draw the new shape from the waistband up to the armpit and then fade out the shape before reaching the cuff.

4. The seams were then closed (as indicated in the image below) by stitching fresh double-needle chain-stitched flat-felled seams using the same thread size and color as the original. If you look closely at the yellow chain stitching, you can see where the new sewing blends in with the old.

6. After cutting away the extra fabric of the bottom band, we rejoined and resewed it to the body with single-needle chain stitching.

7. Finally, the band tabs along the side seams were reattached. Again, if you look very closely, a seamline where the waistband was split and resewn can be seen near the two yellow stitch lines that attach the tabs. Take note of the new chain stitching that joins the old one below the pocket bag.

Williamsburg Garment Company’s objective is to make alterations to improve fit while retaining the original style and construction. This entails matching thread colors and sizes and stitching seams back the same as the original factory sewing.

You might be interested in

When it comes to hemming pants, maintaining the original look is key. Many tailors use what’s known as an “original

With the plethora of DIY hack videos out there, I thought it was crucial to show the proper method.

When searching for a denim expert to work on your treasured jeans, the closest option may not be the best

TCB Jeans crafts history into every stitch, reviving iconic denim like the 1966 Levi’s 501 and the 1955 Levi’s 701

Do you want to know what sets us apart from the competition when it comes to denim alterations? In our latest TikTok video, you can see how we professionally taper the legs of a pair of jeans while also taking in the waist to make them fit just right.

@williamsburggar Denim heaven. The art of taking in the waist with tapering alterations on jeans. We perfect your fit. #denimyourway #denimhead #denimtailor #taperingjeans #jeanswaist #jeanswaistgap #selvedgedenim ♬ MAMBO OVER THE MOUNTAIN – Rick Hirsch

Make sure to follow us on TikTok to see more informative and entertaining videos. @williamsburggar

You might be interested in

When it comes to hemming pants, maintaining the original look is key. Many tailors use what’s known as an “original

With the plethora of DIY hack videos out there, I thought it was crucial to show the proper method.

When searching for a denim expert to work on your treasured jeans, the closest option may not be the best

TCB Jeans crafts history into every stitch, reviving iconic denim like the 1966 Levi’s 501 and the 1955 Levi’s 701