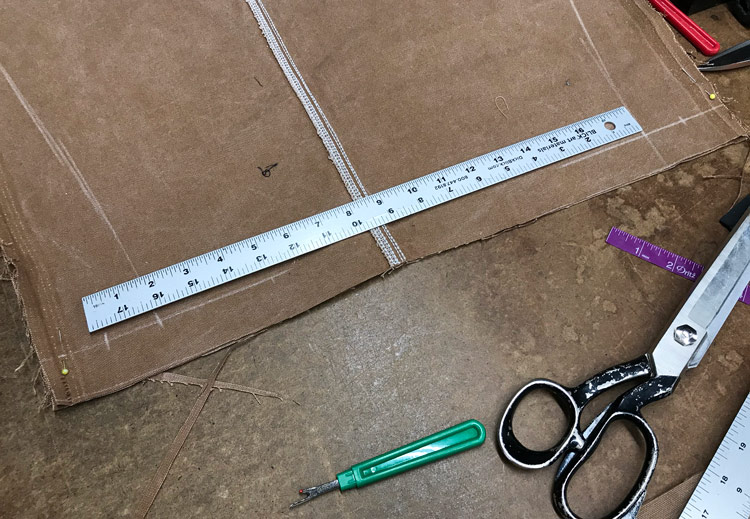

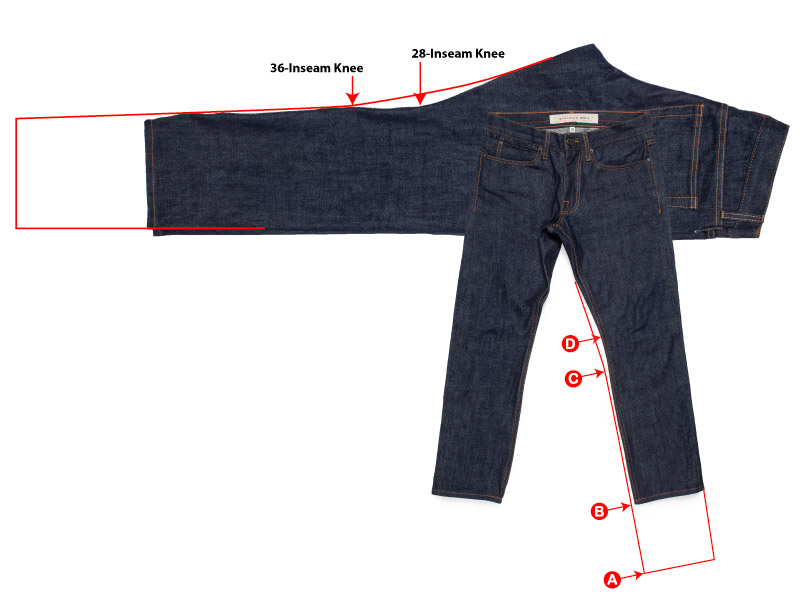

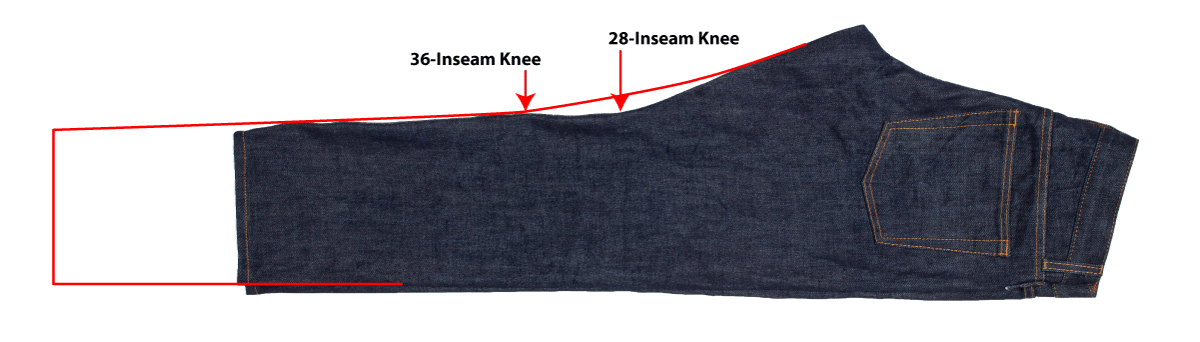

We are just getting started on TikTok creating cool, fun, and informative new videos. Take a look at this one which quickly takes you through the process of how to taper jeans to narrow the leg width on a pair of Samurai selvedge denim constructed with overlock sewing and a single-needle inseam.

Follow us on TikTok and Instagram @williamsburggar so you don’t miss new upcoming videos.