It seems needless to say, selvedge jeans should always be tapered from the inseam. However, some people still take jeans to local tailors or dry cleaners, who are not equipped with proper denim sewing machines and expect them to properly taper their jeans.

Tapering jeans with double-needle chain stitched flat-felled seams

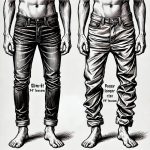

This photo shows an example of tapering from the inseam in-process. These jeans were sewn with a double-needle chain stitched flat-felled (lap seam), so it has to be taken apart at the inseam. With the selvedge outseam shown at the center, the inseam is then trimmed to slim the leg down. Slimming is done from the hem, up to just above the knee, and eases out at the thigh.

A tailor without a feed-off-the-arm chain stitch sewing machine will never properly taper a pair of jeans with lap seam construction. Instead, they may use makeshift single needle sewing from the hem to the knee area. Leaving the area around the crotch and thigh with the original sewing, connecting the new sewing into the original.

For more detail on how we taper jeans constructed with a lap seam, watch our popular Youtube video.

How to taper jeans professionally

How to taper jeans with a single-needle overlocked inseam

Not all jeans have two needle chain stitch lap seam construction. Some have a single-needle topstitched inseam with overlock construction. We tapered the below Levi’s jeans, slimming the legs down and the excess fabric cut from them can be seen underneath.

Most tailors can handle overlocked jeans much easier than lap seams. Overlock sergers are machines commonly used by tailors. However, similar to how traditional tailors may handle lap seam sewing, they will likely remove the original topstitching to just above where the tapering will end. Then use the serger to sew the new leg shape. Finally, to reach high on the leg, so new topstitching can join with the original, the outseams are opened and subsequently closed after topstitching the inseam.

Process for tapering jeans with overlocked inseams as also seen in our TikTok video:

- Cut the inseam to the requested inseam length, plus 3/4″ to 1″ (depending on the hem height)

- Remove the single stitch on the inseam

- Press the inseam flat & draft the taper lines on each leg

- Trim & sew the new leg shape with a serger sewing machine

- Press the inseam to remove slack

- Sew a new single-needle chain stitch on the top of the inseam

- Chain stitch the hem

Depending on the details of the tapering, we first remove the entire original topstitching in order to sew a new unbroken/unjoined line. It doesn’t matter if the taper is to the knee, above the knee, or high into the thigh.

We taper jeans high into the thighs only when we get requests to make the thigh smaller. We always advise, that very little can be done at the thigh. Explaining, that the width of the thigh is in connection to the pattern’s shape. The seat, rise, and curve in the crotch (which affects movement) are all connected. Decreasing the thigh means the curve must be shortened and straightened, which will restrict movement. Taking from the curve also lowers the rise.

In other words, the best we suggest is easing the taper from the knee, high into the thigh, clipping a bit of the curve, thus reducing the thigh to a maximum close to 1/2 inch. We don’t feel comfortable taking much more.

Looking closely, the original overlock stitching can be seen in white thread and the new sewing in tan color. These jeans were tapered high, so we went completely around the crotch.

As demonstrated in the TikTok video below, one of the biggest things that separate our work from tailors and denim specialists is our use of the Union Special feed-of-the-arm chain stitch machine. On single-needle overlock constructed jeans, it allows us to completely topstitch the inseam from hem to hem without opening the outseams.

The Union Special is advantageous with selvedge jeans because you don’t want to disturb the outseams. Tailors who have to rely on tapering at the outseams will destroy the beauty of the selvedge jeans. The photo below is an example of what can happen when you give your jeans to a local tailor who doesn’t specialize in or understand denim. Luckily, he later did some research, found us and we saved his jeans.