Denim nerds, get ready for a reality check. I’m about to debunk some of the myths and misconceptions about the Union Special 43200G that have been circulated for years by brands, publications, and online communities.

As is the case with many things on the Internet, exaggerated claims can quickly become folklore by the regurgitation of stories that weren’t well thought out from the beginning.

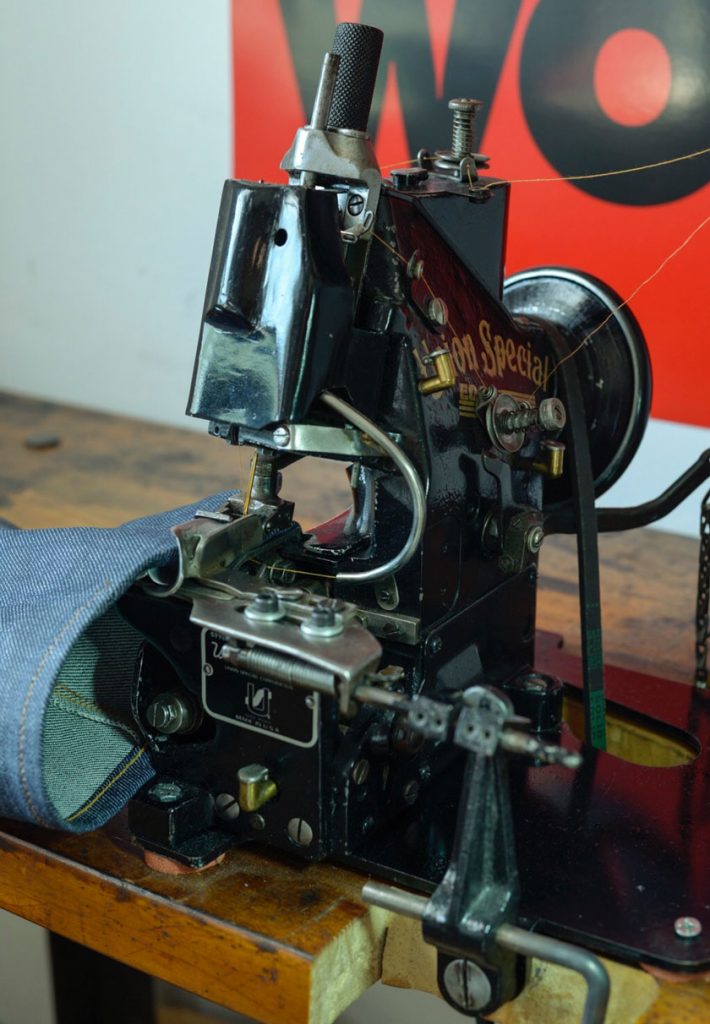

The well-told narrative that the twisting at the hem is caused by a technical error, feed dog flaw, or differential defect in the inner workings of the Union Special 43200G is flawed in and of itself. The roping effect has been overcomplicated to the point where denim fans who don’t know any better will believe that the Union Special 43200G is the only sewing machine capable of producing twisted and puckered hems with chain stitch hemming.

In my research into what denim enthusiasts are being led to believe, I easily discovered statements that I believe are misleading or false. Here are a few examples:

“Any Union Special without the folder will not create the roping effect.”

“There is only one way to chain stitch a selvedge denim hem and that’s on a folder equipped Union Special 43200g. Why you ask? These machines create a desirable roping effect on the hem which is actually caused by a feed differential defect.”

“Roping comes from the 45 degree angle of break-in that makes the hem look like a rope. It’s become part of true denim DNA. Without it, jeans don’t look right to us. And the crazy thing is this comes from a flaw in the Union Special that makes it create a slight twist.”

“Union Special company seems to have replaced the 43200G with other machines in a quest to replicate the same stitch and make it easier to use the machine but this has reduced the tension on the thread. This means you don’t achieve the same roping/puckering as you would with the original.”

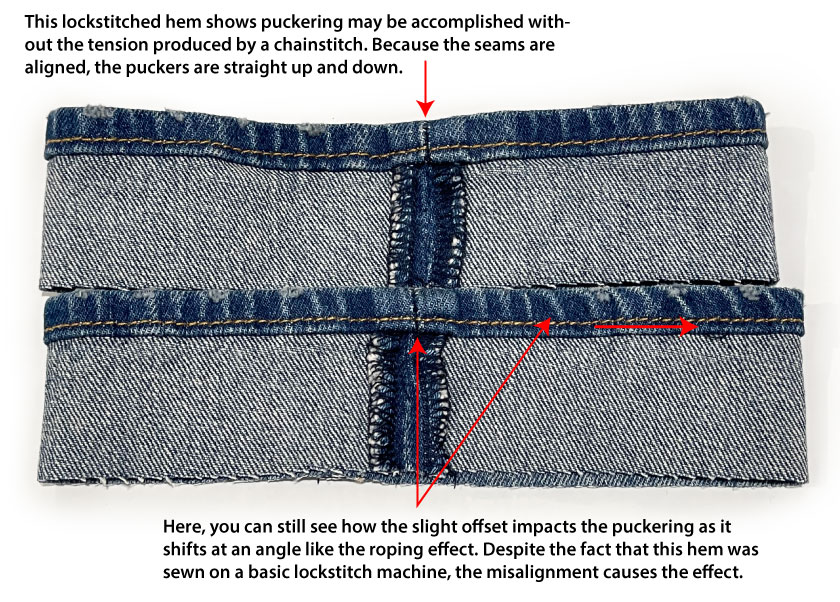

In reality, the roping effect is simply caused by seams that are not lined up.

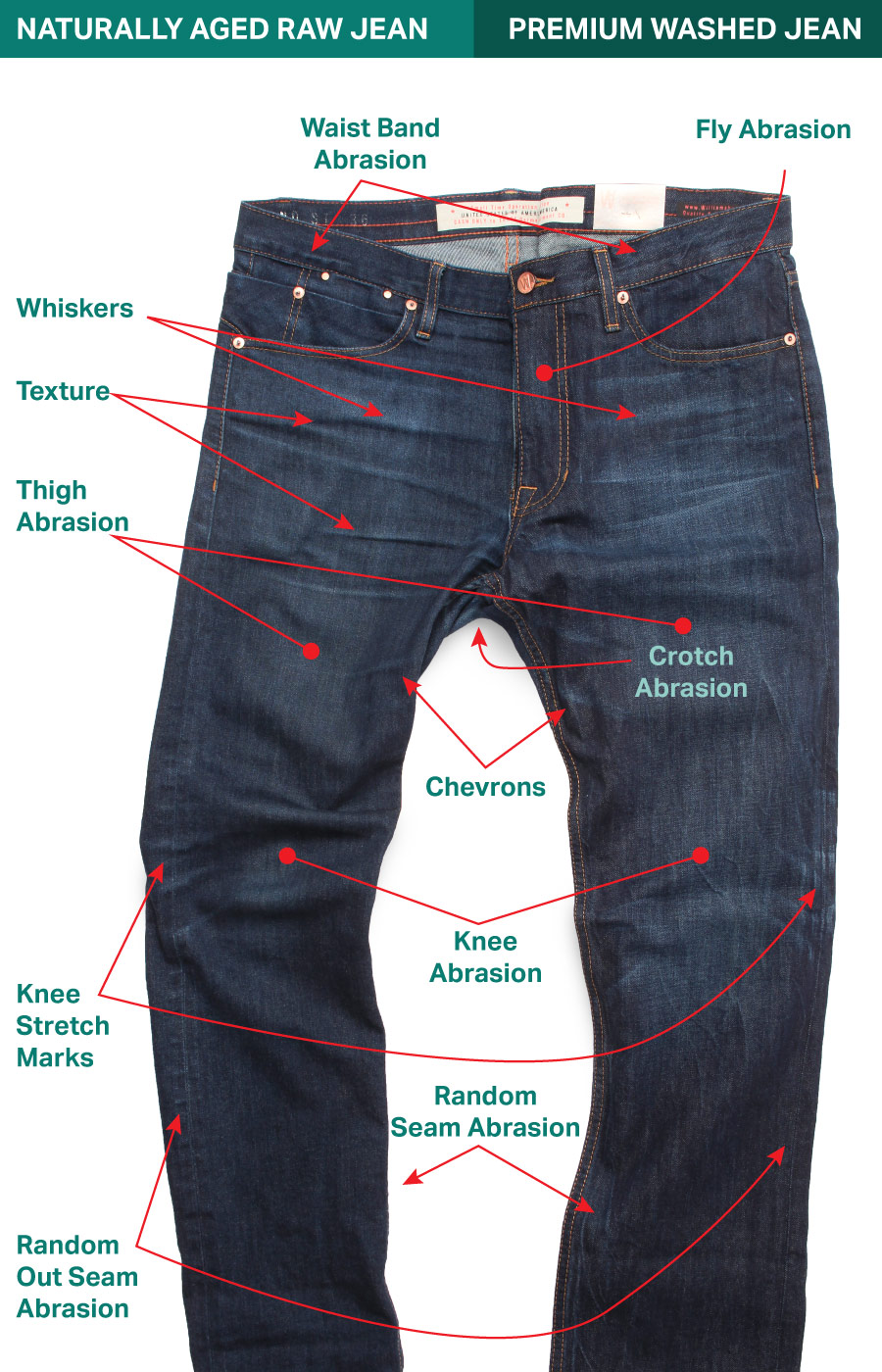

The roping effect is simply caused by seams at the face and undersides of the hem not being lined up. Twisting occurs when the inseams shift in one direction, resulting in the roping effect. The effect becomes more visible with aging and washing. Sometimes factories do this unintentionally, and other times a brand’s designers may request a factory do it on purpose. Most factories make an effort to align the seams, which may be the reason why most jeans do not exhibit a significant degree of twisting.

Furthermore, the stitch type is not a factor in creating the twists and puckers, as seen in the reference example photo below. I, too, was once swayed by rumors and stated in my tapering video that the tension of chain stitching contributes to the roping effect.

Don’t misunderstand me. I think the well-beloved Union Special 43200G is a beautiful old sewing machine. However, production was halted for a reason. It was most likely not due to a differential flaw, cheaper lockstitching, or other nonsense being repeated or made up. The truth is that it only does one function. Although it performs well, some sewing machines can perform the same function as well as other operations.

Purchasing a sewing machine that only does one thing over machines that do multiple tasks equally well or better is a bad idea for factories that must make sound economic decisions. This is most likely why production was halted, as with most discontinued products.