We fix a lot of professional tailor shops and DIY home sewing machine hemming jobs. People learn the hard way that home sewing machines aren’t up to standard when working with denim and then send jeans to us for re-hemming. The thick seamlines are just too much for most domestic machines, so we often find thin broken needles stuck inside of hems.

Others discover that the difference between the quality of denim alterations from a suit tailor or local cleaners, and us is like night and day. That’s because the heavyweight fabric requires specialized machines and the workmanship required for denim is worlds apart from suits, fine trousers, dresses, and style of garments commonly worked on at most tailoring shops.

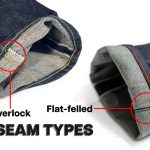

Hems are commonly sewn with chain stitching at jeans factories. Most professional tailors will try to hem jeans on single-needle lockstitch machines, but they often can’t handle the thick fabric or seams. Again, home sewing machines aren’t nearly capable.

When it comes to stitching sizes, professional tailors will use threads that are a little heavier than the small thread sizes which must be used in domestic machines. But still, they usually don’t stock the thicker thread sizes commonly used with denim. The difference is plain to see when it comes to jeans- have them professionally altered by a denim specialist.