You may have tried learning through YouTube or social media videos—but when you’re serious about mastering a craft, you quickly realize that online content can only take you so far.

Read More →

It seems needless to say, selvedge jeans should always be tapered from the inseam. However, some people still take jeans to local tailors or dry cleaners, who are not equipped with proper denim sewing machines and expect them to properly taper their jeans.

Tapering jeans with double-needle chain stitched flat-felled seams

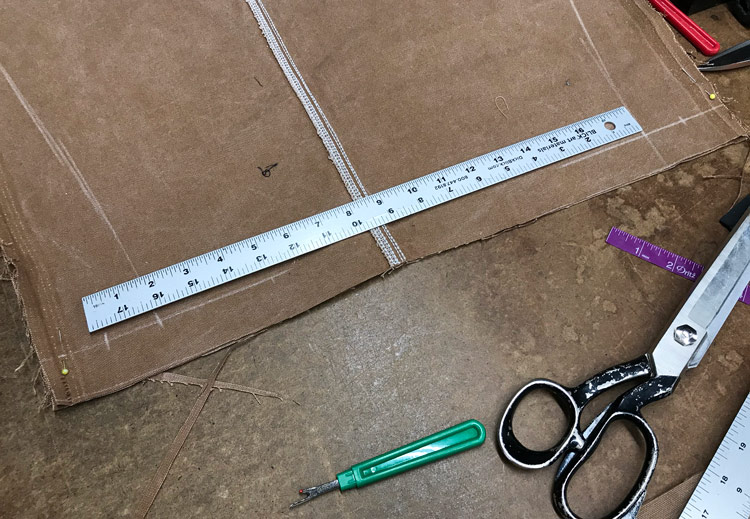

This photo shows an example of tapering from the inseam in-process. These jeans were sewn with a double-needle chain stitched flat-felled (lap seam), so it has to be taken apart at the inseam. With the selvedge outseam shown at the center, the inseam is then trimmed to slim the leg down. Slimming is done from the hem, up to just above the knee, and eases out at the thigh.

A tailor without a feed-off-the-arm chain stitch sewing machine will never properly taper a pair of jeans with lap seam construction. Instead, they may use makeshift single needle sewing from the hem to the knee area. Leaving the area around the crotch and thigh with the original sewing, connecting the new sewing into the original.

For more detail on how we taper jeans constructed with a lap seam, watch our popular Youtube video.

How to taper jeans professionally

How to taper jeans with a single-needle overlocked inseam

Not all jeans have two needle chain stitch lap seam construction. Some have a single-needle topstitched inseam with overlock construction. We tapered the below Levi’s jeans, slimming the legs down and the excess fabric cut from them can be seen underneath.

Most tailors can handle overlocked jeans much easier than lap seams. Overlock sergers are machines commonly used by tailors. However, similar to how traditional tailors may handle lap seam sewing, they will likely remove the original topstitching to just above where the tapering will end. Then use the serger to sew the new leg shape. Finally, to reach high on the leg, so new topstitching can join with the original, the outseams are opened and subsequently closed after topstitching the inseam.

Process for tapering jeans with overlocked inseams as also seen in our TikTok video:

- Cut the inseam to the requested inseam length, plus 3/4″ to 1″ (depending on the hem height)

- Remove the single stitch on the inseam

- Press the inseam flat & draft the taper lines on each leg

- Trim & sew the new leg shape with a serger sewing machine

- Press the inseam to remove slack

- Sew a new single-needle chain stitch on the top of the inseam

- Chain stitch the hem

@williamsburggar This is how we taper jeans with a single-needle top stitched inseam. #selvedgedenim #samuraijeans #denimtailor

♬ original sound – Williamsburg Garment Co.

Depending on the details of the tapering, we first remove the entire original topstitching in order to sew a new unbroken/unjoined line. It doesn’t matter if the taper is to the knee, above the knee, or high into the thigh.

We taper jeans high into the thighs only when we get requests to make the thigh smaller. We always advise, that very little can be done at the thigh. Explaining, that the width of the thigh is in connection to the pattern’s shape. The seat, rise, and curve in the crotch (which affects movement) are all connected. Decreasing the thigh means the curve must be shortened and straightened, which will restrict movement. Taking from the curve also lowers the rise.

In other words, the best we suggest is easing the taper from the knee, high into the thigh, clipping a bit of the curve, thus reducing the thigh to a maximum close to 1/2 inch. We don’t feel comfortable taking much more.

Looking closely, the original overlock stitching can be seen in white thread and the new sewing in tan color. These jeans were tapered high, so we went completely around the crotch.

As demonstrated in the TikTok video below, one of the biggest things that separate our work from tailors and denim specialists is our use of the Union Special feed-of-the-arm chain stitch machine. On single-needle overlock constructed jeans, it allows us to completely topstitch the inseam from hem to hem without opening the outseams.

@williamsburggar Williamsburg Garment Company quickly explains how to professionally taper jeans. Setting us apart from common and amateur tailors, we take the pants apart, redraft the shape, then sew them back together following the original factory’s construction. #denimhead #selvedgedenim #denimtailor #taperingjeans

♬ original sound – Williamsburg Garment Co.

The Union Special is advantageous with selvedge jeans because you don’t want to disturb the outseams. Tailors who have to rely on tapering at the outseams will destroy the beauty of the selvedge jeans. The photo below is an example of what can happen when you give your jeans to a local tailor who doesn’t specialize in or understand denim. Luckily, he later did some research, found us and we saved his jeans.

You might be interested in

You may have tried learning through YouTube or social media videos—but when you’re serious about mastering a craft, you quickly

If you’ve ever typed how to take in the waist of jeans into Google, you’ve probably seen a lot of

The first brand in our new lineup was TCB Jeans, a company out of Kojima, Japan that builds its reputation

The leg opening measurement is a critical factor in how your jeans fit over your shoes and shape your overall

We recently added an option for special request alterations that fall outside of our regular services. For example, shortening the inseam on these vintage Levi’s Engineered Jeans is far more time-consuming than chain stitch hemming. After all, you would not want to lose the sloped hem shape that uniquely identifies these by cutting them straight like regular jeans. This calls for more than our trouser or chain stitch hemming services.

For this style, we first record the size and shape of the original hem by creating a pattern to recut the newly positioned leg opening. After, we remove the inside panel at the hem stitch by stitch to keep it intact.

These jeans have a twisted leg, so measuring the inseam can be tricky. On jeans with a leg twist, you can’t just follow the inseam line down with the measuring tape. Instead, you must follow the shape of the leg down without turning under the seam. Following the inseam line on a twisted leg will ultimately mean that leg will be slightly shorter.

Finally, after the jeans are cut-down, the original inside hem panels are sewn back into the leg opening. Finished, the jeans keep the look of the original factory sewing and stitching while being customized to a concise length.

You might be interested in

Most people simply don’t realize that tailoring jeans or knitwear is a specialized service. It’s not something every tailor does

You may have tried learning through YouTube or social media videos—but when you’re serious about mastering a craft, you quickly

If you’ve ever typed how to take in the waist of jeans into Google, you’ve probably seen a lot of

The leg opening measurement is a critical factor in how your jeans fit over your shoes and shape your overall

We are just getting started on TikTok creating cool, fun, and informative new videos. Take a look at this one which quickly takes you through the process of how to taper jeans to narrow the leg width on a pair of Samurai selvedge denim constructed with overlock sewing and a single-needle inseam.

Follow us on TikTok and Instagram @williamsburggar so you don’t miss new upcoming videos.

@williamsburggar This is how we taper jeans with a single-needle top stitched inseam. #selvedgedenim #samuraijeans #denimtailor

♬ original sound – Williamsburg Garment Co.

You might be interested in

You may have tried learning through YouTube or social media videos—but when you’re serious about mastering a craft, you quickly

If you’ve ever typed how to take in the waist of jeans into Google, you’ve probably seen a lot of

The first brand in our new lineup was TCB Jeans, a company out of Kojima, Japan that builds its reputation

The leg opening measurement is a critical factor in how your jeans fit over your shoes and shape your overall

We take a quick and humorous look at the alterations process of hemming a t-shirt. Those looking to shorten the length of a tee or lightweight knit shirt that’s too long, or simply trying to restyle the look, should have a peek at this new tutorial video “how to hem a t-shirt.”

You might be interested in

Most people simply don’t realize that tailoring jeans or knitwear is a specialized service. It’s not something every tailor does

You may have tried learning through YouTube or social media videos—but when you’re serious about mastering a craft, you quickly

Got a twisted leg on your jeans? If one leg seam always seems to drift to the front or back,

Why the Same Inseam Length May Lead to Different Results

You love work pants but wish they came with a modern fit for casual wear. Here we explain the step-by-step process that went into tapering a pair of triple-needle flat-felled chain-stitched inseam Carhartt carpenter pants from a 20-inch wide leg, down to a 15-inch opening.

It’s a job that not many tailors or alterations services do because of the skill and equipment needed. As a denim factory with all the heavy-duty machinery required to deal with triple-needle stitching at both the out-seam and inseam of work pants, one can argue our added enhancements look better than the original manufacturing.

The tapering process

Step – 1: Inseam length

In the above before & after photo, you can note the lines drawn above the hem of the pants. It marks the requested inseam length. 1-inch is added to account for the two 1/2-inch folds of the hem.

From the start, we cut the inseam to match the customer’s requested inseam length. However, the inseam always grows during the sewing process when we put the inseam back together. The fabric stretches while being pulled through the flat-felled sewing machine. Pressing at the end of sewing also causes the fabric fibers to flatten and grow. We leave the length as-is, which is usually longer, anticipating the pants to relax back into place after wash and wear.

Step – 2: Undo the inseam

The requested inseam for this pant was 28-inches. After cutting the pants down to the new length, plus 1-inch, we pull the chain stitching apart at the inseam. This is a fairly quick process. For factories, the chain stitch is the strongest, and most effortless to pull apart in cases when re-sewing is needed.

Step – 3: Re-Draft leg shape

The pants are opened and placed on the table to re-draft the leg shape. The leg of this Carhartt carpenter initially measured 20-inches in total circumference. The customer requested to bring it down to 15-inches.

Below, note the leg opening measurement is 16 1/8 inches. 1 1/8-inches is added for seam allowance. In the photo above, markings for the knee can be seen. It highlights the area where we make the turn towards the crotch.

Step – 4: Sewing

Finally, using the three-needle flat-felled sewing machine, the inseam is closed, and the hem is chain-stitched with a Union Special sewing machine. Last, the garment is pressed and packed for shipping back to the customer.

Under our alterations services menu, we offer triple-needle tapering, Double-needle, and single-needle tapering services. We charge slightly more for triple-needle work because of the machine set-up and change-over.

You might be interested in

You may have tried learning through YouTube or social media videos—but when you’re serious about mastering a craft, you quickly

Got a twisted leg on your jeans? If one leg seam always seems to drift to the front or back,

When it comes to hemming pants, maintaining the original look is key. Many tailors use what’s known as an “original

With the plethora of DIY hack videos out there, I thought it was crucial to show the proper method.

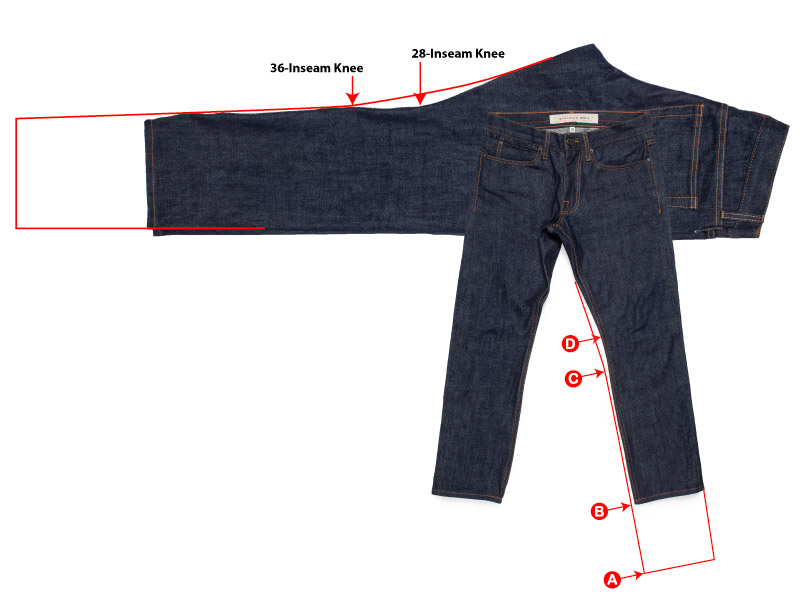

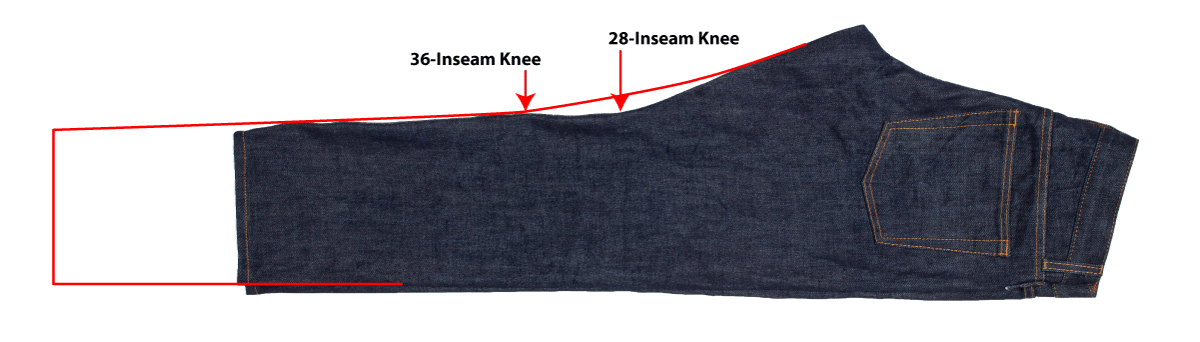

When smaller and mid-sized denim brands manufacture jeans, they try to cover a wide range of customers by producing jeans as long as 34 to 36 inches. For those who have to shorten jeans or pants offered by most better producers, we would like to share this example of how to hem a pair of jeans and achieve the original optimal fit through the leg shape.

- A – The leg opening is also known as the hem. The inseam of this jean originally measured 34-inches long.

- B – Hemming is shortening the inseam length. These jeans have been hemmed to measure 28-inches in length. The leg opening appears slightly smaller at this point in the photo, however, with added tapering, the hem has been trimmed to the original size. It is only because the width of a tapered pant gets larger the higher up you go. The raised leg opening looks smaller at this point as compared with the original width.

- C – This is the original knee position of the uncut 34-inseam leg (12 ½ ” below the crotch). The knee is where the leg circumference begins enlargement into the thigh. Without raising the knee position on shortened jeans, the area around the knee will be bigger than it was originally designed.

- D – By tapering, we trimmed the denim slightly to match the original measurements at the lower leg and raised the knee placement so the leg keeps its original contoured shape. The new knee is located 10 ½ ” below the crotch. Without raising the knee, you can see how much extra fabric would remain if hemming alone.

Unless you are up for laying out good money for a pair of custom-made jeans, it is likely a brand that offers multiple inseam options will simply make its standard size and cut the length down before shipping, without consideration of moving the knee position. Like most brands, if you order hemming without additional tapering, we would do the same.

Let’s say a brand offers pants or jeans sizes 30×28, 30×29, 30×30, and 30×31. That’s four different inseams within a single waist size. To have the proper knee location on each and every size would require four different sets of patterns. One pattern per waist size, per each inseam length. It is unlikely a brand would do so unless they are a mass producer. Now that you have an understanding of why it is so difficult to find pants off-the-shelf in a multitude of inseam sizes and the behind-the-curtain factors associated with those who may, let’s get to the workaround.

Our suggestion is merely hemming jeans and adding tapering. For this is a simple alteration where we take apart the legs, make the adjustments, then put them back together. If constructed with a lap or flat-felled seam with double stitch lines, we only need to take apart the inseam. If the jeans are constructed with a serger and single-needle stitch line at the inseam, we start by removing the inseam’s topstitching. Next, we draft the new shape at the inseam and sew it back together following the original thread colors. The outseam is never touched.

Before explaining how to hem jeans with added tapering, we will first explain the two types of construction found in most jeans. Inseam design is especially important when it comes to tapering but it does not matter for hemming.

- E – Denim and work clothing most often are produced with a flat-felled seam. It has a double-needle chain stitch (sometimes 3-needles in work pants) at the inseam for strength and durability. It would be surprising if your local cleaners, tailor, or even most denim specialists have the machine required to sew this seam. It is mainly found in factories and small-batch jeans makers. Without the need to open the outseam, it sews the topstitching and closes the seam in a single pass.

- F – Pictured in both images are selvedge (selvage) outseams. The vast amount of jeans sold will not be produced in selvedge denim. Top-end denim brands will offer selvedge in their line-ups. Some only offer selvedge. Selvedge does not factor in the quality of the fabric. When jeans are not produced in selvedge denim, the outseams can also be constructed with an overlocked edge and pressed open. Low-end denim producers routinely close the outseams with a closed overlock for speed.

- G – The hem or leg opening on jeans is commonly sewn with chain stitching in better denim. Low-end makers will frequently use a standard lock-stitch. Home sewers and fine tailors often run into difficulty working with the hem using sewing machines not suitable for sewing through multiple layers of denim fabric.

- H – Makers of very heavy jeans will construct them with a single-needle topstitched inseam to avoid the difficulties of folding and sewing through multiple layers of thick denim. On women’s and skinny jeans, single-needle topstitch construction is also most often used for comfort and flexibility. Lower-priced jeans also prefer the serger seam for ease and speed.

The heavy lifting in the leg shape of jeans is at the inseam. Selvedge and a good deal of non-selvedge jeans have a straight outseam from the hem-to-hip curve. Unless the jeans have a flared or bootcut, tapering should be done at the inseam. Tapering selvedge from the outseam would be unforgivable.

Even though outseam tapering alterations and regular lockstitch stitched hems are simply amateur, there are commercially produced YouTube videos where one of the world’s biggest and most popular denim brands gets it wrong. Perhaps because it’s faster, more convenient or they don’t have the right equipment and skilled operators in their stores for factory quality alterations. Good advice before letting anyone begin work on your jeans – ask how they intend to do it.

For more information on hemming and tapering, check out our many other articles and alteration services.

You might be interested in

You may have tried learning through YouTube or social media videos—but when you’re serious about mastering a craft, you quickly

If you’ve ever typed how to take in the waist of jeans into Google, you’ve probably seen a lot of

The first brand in our new lineup was TCB Jeans, a company out of Kojima, Japan that builds its reputation

The leg opening measurement is a critical factor in how your jeans fit over your shoes and shape your overall