Saturday, September 27, 2025🕚 11:00 AM – 6:00 PM📍 59 Orchard Street, Lower East Side, NYC If you’re a fan of vintage denim, creative customization, and the culture surrounding rugged American workwear, Denim Edition might be the best denim show you’ll attend

Read More →

Even in 2025, many people still take their jeans to the dry cleaners for alterations. And most have never even considered that you can professionally hem or crop a T-shirt. We’re trying to change that.

This month, our ads began appearing across MTA subway entrances along the L Train, including key locations in Williamsburg, Brooklyn and Manhattan. It marks the start of a long-overdue public education campaign—not just for our brand, but for the concept of denim tailoring itself.

Most people simply don’t realize that tailoring jeans or knitwear is a specialized service. It’s not something every tailor does well, and it requires more than a sewing machine and thread. The right tools, machines, and knowledge matter. And unless you’ve spent time in the industry—or been burned by a bad alteration—you probably haven’t had a reason to think about it. Until now.

The Problem With Traditional Tailoring

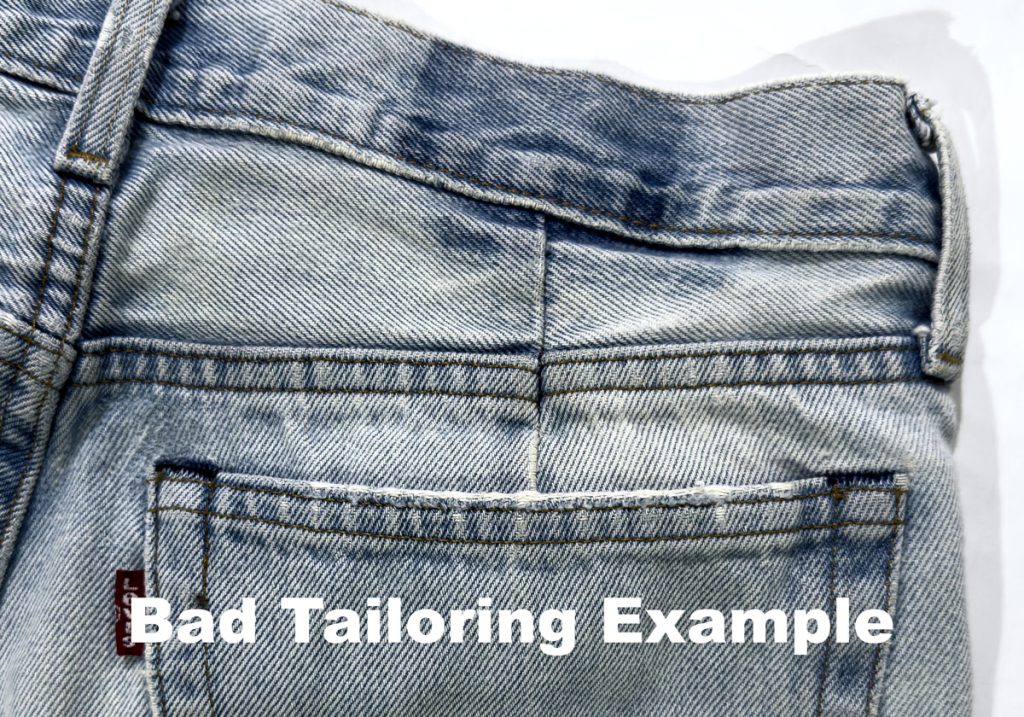

Let’s start with jeans. When someone walks into a generic tailor and asks to take in the waist, two things usually happen: they either get visible darts along the back waistband or a mismatched seat seam that doesn’t look anything like the original construction.

Some tailors try to mimic our method—removing excess fabric from the center back seat seam—but they don’t have the right equipment to finish the job correctly. Most jeans are sewn with a flat-felled, double-needle chainstitched seam that requires industrial machinery. At Williamsburg Garment Company, we use the same types of machines that denim factories do. Why? Because we make jeans—not just repair them—and we rebuild every altered section to factory specs.

The same applies to hemming. One of the more common gimmicks we see is the so-called “original hem” reattachment. Tailors cut the hem off, shorten the legs, and stitch the original hem piece back on. It creates an awkward, unnecessary seam above the hemline—and exists only because they can’t sew cleanly through multiple layers of denim.

What most people don’t realize is this: the wear, twist, and fade of the original hem naturally returns after one or two washes. With the right thread, tension, and stitch, the new hem will age just like the original—without tricks.

T-Shirts Are No Different

If you’ve ever had a T-shirt hem curl, stiffen, or lose stretch after a tailoring job, chances are it was sewn with the wrong machine. Most shops don’t have a coverstitch machine—the industrial standard for hemming knits.

That’s why T-shirt hemming is part of our campaign too. Because tailoring knitwear also requires precision equipment. A proper hem on a tee should stretch, flex, and sit flat—just like it did before. And that takes the right tools.

Tailoring That’s Built for the Way People Live Now

The other part of this campaign is accessibility. People often ask, “Do I have to be in New York to use your services?” The answer is no. You don’t even have to leave home.

We’ve built our system so anyone in the U.S. can get professional denim and knitwear tailoring.

- You order online

- Using 2-way shipping, we email you a shipping label

- You send your garments to us

- We tailor them and ship them back

We like to say: if you can order a pizza online, you can order tailoring services from us. Just like choosing your toppings, crust style, and sides, our ordering pages walk you through clear dropdown menus to select exactly what you need—whether it’s hemming, tapering, waistband adjustments, or more.

And if you come across a term you’re unfamiliar with—like “inseam type” or “bar tack”—there’s likely a link right there to a help article, video, or visual example that breaks it down. We’ve built our platform to be intuitive, but we also understand that not everyone speaks denim. That’s why the information is always within reach.

Still have questions? Call us during business hours and you’ll speak to a real person—not an automated phone maze, robo-operator, or AI gatekeeper. Just denim people who know exactly what you’re talking about—and what your jeans need.

Putting Denim Tailoring Where People Can See It

These subway ads are the first step in a year-long marketing effort to bring denim tailoring out of the shadows. Until now, most people have either accepted poor alterations—or never even knew there was a better option.

So if you’re walking past the Bedford Avenue Station or through Manhattan along the L line, and you spot our billboard, know that it’s more than an ad. It’s a message:

There’s a better way to tailor jeans.

There’s a better way to crop your tees.

And you don’t need to be in New York to get it done right.

You might be interested in

If you’ve ever typed how to take in the waist of jeans into Google, you’ve probably seen a lot of

Got a twisted leg on your jeans? If one leg seam always seems to drift to the front or back,

Why the Same Inseam Length May Lead to Different Results

Repairing Belt Loops: Why Quality Matters Belt loops are one of those essential details on your pants that you probably

If you’re serious about denim—about understanding how jeans are made, how they’re designed, and how the pieces really come together—this is the workshop you’ve been waiting for.

This fall, I’ll be leading a new Denim Workshop inside the Williamsburg Garment Company studio in Brooklyn. The workshop is produced by Williamsburg Garment Company, Maurice Malone (the brand), and MakingABrand.co. It’s designed for aspiring denim designers, fashion students, and apparel professionals who want real-world experience and hands-on training in how to make jeans using professional machines and methods.

Classes will be held on Sunday evenings, starting October 26, 2025. I’ll be teaching live in the same studio where we sew jeans every day for our brands.

If you’re interested, sign up now to the emailing list at WilliamsburgGarment.com, MauriceMaloneUSA.com, or MakingABrand.co. You can also follow any of our social media channels for updates when enrollment opens.

“Denim Workshop is part of my goal to help inspire and develop the next generation of great denim designers.“

This isn’t a class for hobbyists or home crafters.

You may have tried learning through YouTube or social media videos—but when you’re serious about mastering a craft, you quickly realize that online content can only take you so far. You want to understand the process in real time, ask questions, and get answers that aren’t surface-level. That’s what this workshop is built for.

Over the course of the program, you’ll:

- Learn how to make jeans using real industrial machines and techniques

- Understand stitch types, seam construction, and when to use them

- Watch my team build a full pair of jeans from beginning to end, with full transparency

- Learn the basics of pattern making, and how to adjust fit through sample sewing

- Construct a fit sample, make corrections, and finalize your own personalized pattern

- Sew a complete, wearable pair of jeans using professional techniques

You’ll walk away with a finished garment and a real understanding of how jeans are made—not just on paper, but in practice.

Class sizes will be limited so that everyone gets hands-on time and personal guidance. This is an immersive experience, not a passive demo.

If that sounds like what you’ve been searching for, join the emailing list today. More details will be announced soon.

Let’s make some jeans.

You might be interested in

If you’ve ever typed how to take in the waist of jeans into Google, you’ve probably seen a lot of

The first brand in our new lineup was TCB Jeans, a company out of Kojima, Japan that builds its reputation

The leg opening measurement is a critical factor in how your jeans fit over your shoes and shape your overall

Washing raw denim has long been a topic of debate. Some purists believe in waiting as long as possible, while

At Williamsburg Garment Company, we’ve spent years perfecting denim fit. Whether it’s hemming selvedge, tapering heavyweight raw denim, or completely re-engineering the shape of jeans, we’ve become the go-to name in denim alterations across the U.S. Recently, we’ve taken what we do best and combined it with something new—but long overdue: selling premium jeans from other top-tier brands directly through our platform and studio.

This is not your typical retail expansion. What sets WGC apart is that we’re not just a place to buy jeans—we’re the place to make them fit perfectly. No other denim retailer in the country offers this level of specialized tailoring in-house. Big-box stores might provide alterations, but their tailors aren’t trained in denim construction. While specialty denim shops may offer high-quality jeans, their tailors typically only perform basic chainstitch hemming and maybe repairs. Williamsburg Garment Company is something entirely different. We are a small denim factory. We sew jeans from scratch. We have the machines, the expertise, and a team led by a legendary designer who understands every part of a jean’s construction.

Now, customers can shop from a curated collection of hard-to-find brands and have them tailored by the most capable denim experts in the country—before the jeans ever leave our shop.

The first brand in our new lineup was TCB Jeans, a company out of Kojima, Japan that builds its reputation on craftsmanship, historical research, and dedication to the original spirit of American denim. TCB specializes in reproduction jeans—faithful recreations of denim from the 1940s, ’50s, and ’60s, made with remarkable attention to period-correct details. That means everything from the fabric weave to the thread gauge, from the rivets to the paper patch, is chosen to match garments from the original era.

We were introduced to TCB by one of our team members, Amalia Nissan, who began working with us after returning from a sourcing trip to Japan. Already a fan of TCB’s 50s jeans—and a serious denim enthusiast—she took it upon herself to meet with factories, tour workshops, and build relationships with makers who live and breathe reproduction denim. TCB stood out from the rest—not just for their product, but for their clear dedication to denim that’s made to be worn hard and lived in.

That philosophy matches our own. We don’t believe in precious jeans meant to sit on a shelf. We believe in garments that are worn, faded, repaired, and reshaped over time. And we believe the right pair of jeans doesn’t just fit—it becomes part of your life.

By offering TCB Jeans at Williamsburg Garment Company, we’re creating a new experience for denim lovers. You no longer have to buy jeans from one shop and send them to another for proper alterations. Now you can buy and tailor in one place—with no compromises in craftsmanship, detail, or fit.

Shop or find out more about TCB Jeans →

TCB was the perfect brand to kick off our retail expansion—not just because of their product, but because of what they represent. Their commitment to historical accuracy, quality craftsmanship, and denim that’s meant to be truly worn mirrors everything we stand for at Williamsburg Garment Company. Like us, they believe jeans should be built with purpose, designed with care, and lived in fully. Starting with TCB set the tone for the kind of brands we’re proud to carry: those that value authenticity, make no compromises in construction, and understand that the best jeans are the ones that become part of your everyday life.

You might be interested in

You may have tried learning through YouTube or social media videos—but when you’re serious about mastering a craft, you quickly

If you’ve ever typed how to take in the waist of jeans into Google, you’ve probably seen a lot of

The leg opening measurement is a critical factor in how your jeans fit over your shoes and shape your overall

Washing raw denim has long been a topic of debate. Some purists believe in waiting as long as possible, while

The leg opening measurement is a critical factor in how your jeans fit over your shoes and shape your overall look. Whether you’re shopping online, comparing styles, or getting your jeans tapered, knowing how to measure the leg opening properly ensures accurate sizing and a better fit.

In this guide, we’ll break down the correct method for measuring the leg opening on jeans—just like we do in our professional denim alteration shop at Williamsburg Garment Company.

📏 What Is the Leg Opening on Jeans?

The leg opening is the width of the bottom hem of a pant leg. This measurement determines how fitted or wide the jeans will fall over your shoes. Slim, straight, bootcut, and wide-leg jeans all have different leg opening sizes, which impact the overall silhouette of the jeans.

🔥 Why Does It Matter?

✅ Helps compare different fits when buying jeans online

✅ Essential for tapering alterations to ensure a balanced look

✅ Impacts how jeans sit on top of shoes

🛠 Step-by-Step: How to Measure the Leg Opening on Jeans

Follow these simple steps to accurately measure the leg opening of your jeans.

1️⃣ Lay the Jeans Flat

- Place your jeans on a flat surface, like a table or the floor.

- Smooth out any wrinkles, but do not stretch the fabric.

🔽 See the diagram below for proper positioning:

[Insert drawing: Jeans laid flat with a focus on the hem area]

2️⃣ Align the Hem Evenly

- Make sure both layers of fabric at the bottom hem are lined up evenly.

- Some jeans, especially washed or worn pairs, may have twisting in the leg—try to align them as close to their natural shape as possible.

🔽 Illustration showing the hem properly aligned:

[Insert drawing: Close-up of the bottom hem, ensuring both sides are even]

3️⃣ Measure Across the Bottom Hem

- Use a soft measuring tape and place it edge to edge across the leg opening.

- Do not curve or wrap the tape—measure in a straight line.

- Write down this measurement.

🔽 Example of correct measuring technique:

[Insert drawing: Measuring tape laid straight across the hem from one edge to the other]

4️⃣ Double the Measurement

- Since jeans are measured flat, you’ll need to double the number to get the full leg opening circumference.

- Example: If your measurement is 8 inches, the total leg opening is 16 inches.

🚨 Common Mistakes to Avoid

🔴 Not laying the jeans completely flat – Wrinkles and folds can throw off your measurement.

🔴 Measuring diagonally – Always measure straight across for accuracy.

🔴 Ignoring leg twisting – Some jeans may have a twist in the leg seam due to shrinkage or wash effects. Align them properly before measuring.

👖 How the Leg Opening Affects Fit

The leg opening measurement is key to understanding different jean styles:

- Slim Fit Jeans – Narrow leg opening (usually 12″–14″)

- Straight Fit Jeans – More room at the ankle (14″–16″)

- Bootcut Jeans – Slight flare to fit over boots (16″–18″)

- Wide-Leg Jeans – Loose fit with a larger leg opening (18″+)

📢 Thinking about tapering your jeans? If you want a smaller leg opening, professional tapering is the best way to achieve a clean, proportional fit. Check out our denim tapering service for expert alterations.

🎥 Watch the Video: Measuring the Leg Opening

For a full demonstration, watch our step-by-step video on how to measure the leg opening on jeans featuring Maurice Malone of Williamsburg Garment Company.

📌 Subscribe for more denim fit and alteration guides!

This blog post is now optimized for readability, SEO, and usability with step-by-step instructions and custom drawings to assist readers. I’ll generate the requested illustrations now. Stay tuned! 🎨📏

You might be interested in

You may have tried learning through YouTube or social media videos—but when you’re serious about mastering a craft, you quickly

If you’ve ever typed how to take in the waist of jeans into Google, you’ve probably seen a lot of

The first brand in our new lineup was TCB Jeans, a company out of Kojima, Japan that builds its reputation

Washing raw denim has long been a topic of debate. Some purists believe in waiting as long as possible, while

Washing raw denim has long been a topic of debate. Some purists believe in waiting as long as possible, while others argue that washing enhances the fabric’s character. But knowing how to wash raw denim jeans properly can make all the difference in maintaining the integrity of the denim while preserving those hard-earned fades.

In their latest video, Benzak Denim Developers demonstrate their recommended method for washing raw denim for the first time, using a well-worn pair of BO2 Straight jeans made from their 10-year anniversary denim. They cover everything from prepping your jeans before the wash to selecting the right machine settings—ensuring your denim stays in top shape without unnecessary shrinkage or fading.

If you’ve ever wondered when to wash, why washing matters, or most importantly, how to wash raw denim jeans, this video lays it all out. Watch below to see how a year of wear transforms after a proper wash.

You might be interested in

You may have tried learning through YouTube or social media videos—but when you’re serious about mastering a craft, you quickly

If you’ve ever typed how to take in the waist of jeans into Google, you’ve probably seen a lot of

The first brand in our new lineup was TCB Jeans, a company out of Kojima, Japan that builds its reputation

The leg opening measurement is a critical factor in how your jeans fit over your shoes and shape your overall