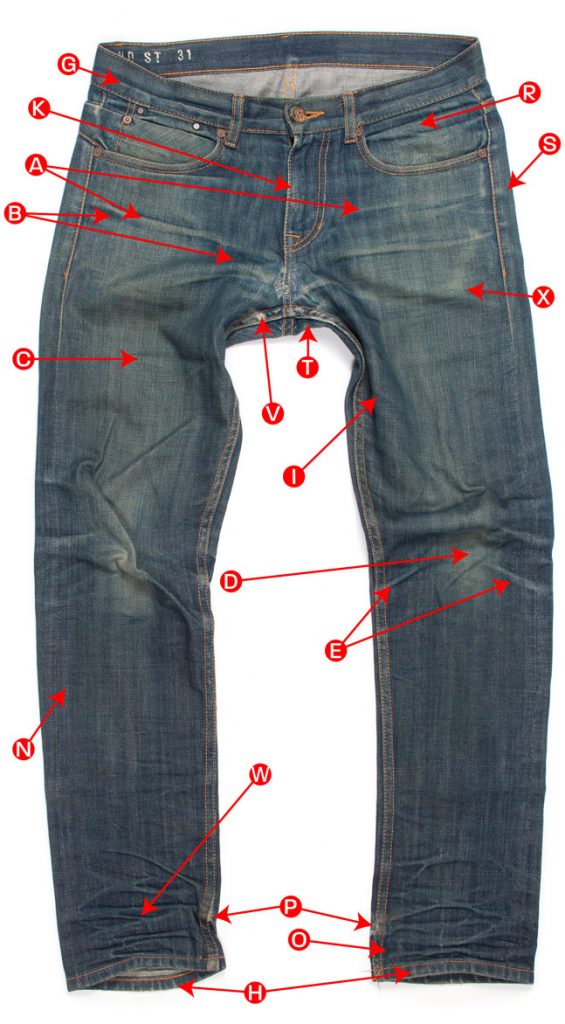

Looking at the images above, it’s easy to see why you don’t need to be a denim guru to see why some individuals prefer to let their jeans fade naturally over time from the raw denim state rather than buying jeans that have been artificially aged through manufactured washing processes. The details and three-dimensional texture that come from time and natural wear are too complicated for the fast industrial washing process to recreate.

Summary

Denim honeycombs are made from compression and decompression at the back of the knees. When denim begins stiff, such as raw denim, the initial breaking points in the bends become the points of least resistance, resulting in repeated bends and well-defined folds.

Denim honeycombs are so named due to their striking resemblance to honeycombs. They are formed as a result of compression and decompression at the back of the knees. When denim begins stiff, such as raw denim, the initial breaking points in the bends become the points of least resistance, resulting in repeated bends and well-defined folds.

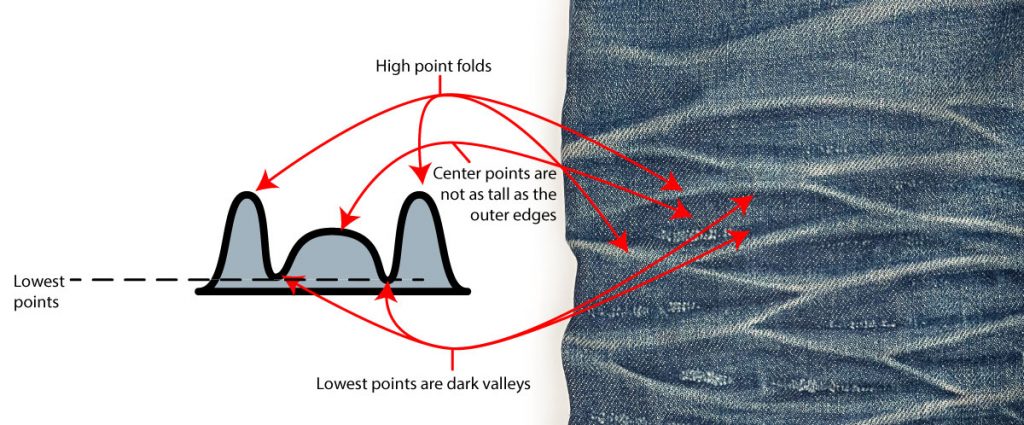

The highest points, like whiskers, undergo the most abrasion and hence lighten the most in color. The lower points remain darker, resulting in transitional fades between them.