We have extensive experience hemming jeans and pants, as well as providing fittings to numerous customers. One of the things we often hear from those who request the same inseam without going through a fitting session is that they ordered the same inseam across their various jeans and pants, but some came out longer or shorter than others. Therefore, when a customer arrives with multiple jeans or pants and requests the same length throughout the styles, we explain why it could be a mistake.

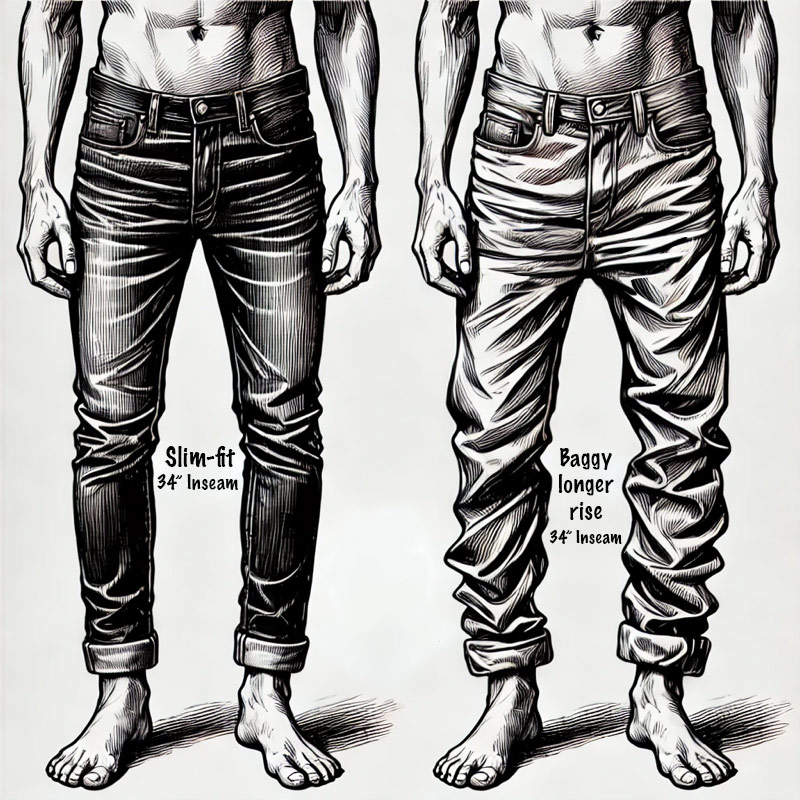

The same inseam length can look different on various styles of jeans and pants. For instance, jeans or pants with identical waist measurements and inseam lengths but different rise measurements will fit differently. A pair with a 1-inch longer rise may result in a hem that falls 1 inch lower.

Similarly, the waist opening measurement affects where the jeans or pants sit on your body. Larger waist openings cause them to sit lower on your hips, making them appear longer even if the rise and inseam are the same.

Moreover, the labeled waist size doesn’t always match the actual waist measurement, and even the same size in the same brand can vary. While the same brand and style are more likely to fit the same, it’s not always guaranteed.

For those seeking consistency in the positioning of their jeans and pants, it is advisable to invest some extra time in separately fitting each pair. It would be a mistake to assume that the same length would yield the same results across styles. Therefore, always measure each pair individually for hemming.