Even in 2025, many people still take their jeans to the dry cleaners for alterations. And most have never even considered that you can professionally hem or crop a T-shirt. We’re trying to change that.

This month, our ads began appearing across MTA subway entrances along the L Train, including key locations in Williamsburg, Brooklyn and Manhattan. It marks the start of a long-overdue public education campaign—not just for our brand, but for the concept of denim tailoring itself.

Most people simply don’t realize that tailoring jeans or knitwear is a specialized service. It’s not something every tailor does well, and it requires more than a sewing machine and thread. The right tools, machines, and knowledge matter. And unless you’ve spent time in the industry—or been burned by a bad alteration—you probably haven’t had a reason to think about it. Until now.

The Problem With Traditional Tailoring

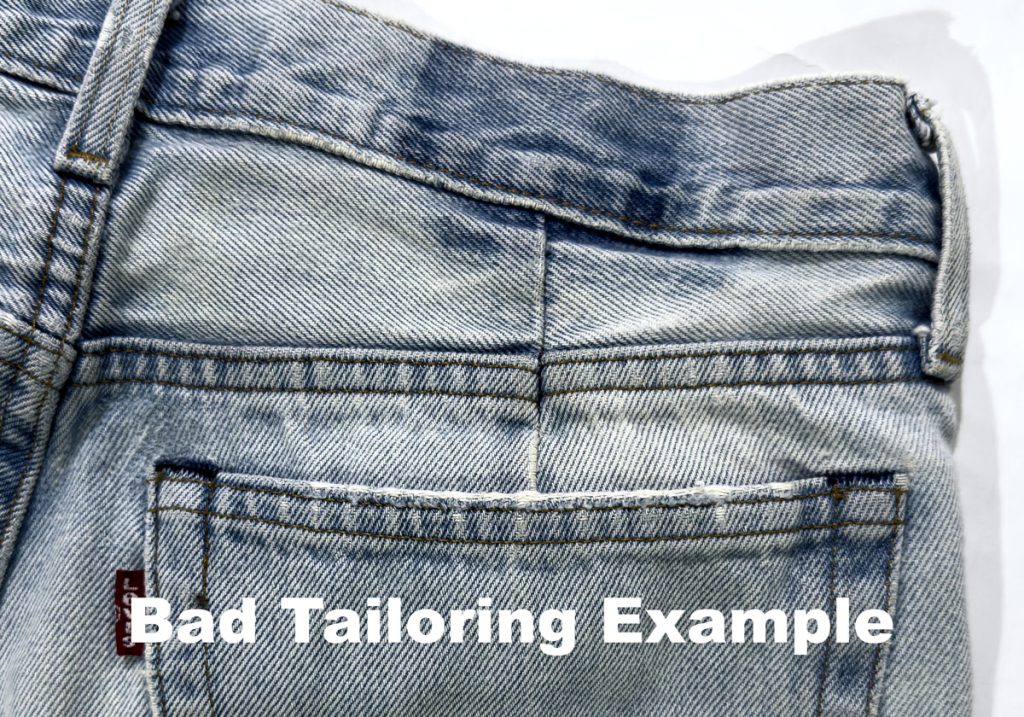

Let’s start with jeans. When someone walks into a generic tailor and asks to take in the waist, two things usually happen: they either get visible darts along the back waistband or a mismatched seat seam that doesn’t look anything like the original construction.

Some tailors try to mimic our method—removing excess fabric from the center back seat seam—but they don’t have the right equipment to finish the job correctly. Most jeans are sewn with a flat-felled, double-needle chainstitched seam that requires industrial machinery. At Williamsburg Garment Company, we use the same types of machines that denim factories do. Why? Because we make jeans—not just repair them—and we rebuild every altered section to factory specs.

The same applies to hemming. One of the more common gimmicks we see is the so-called “original hem” reattachment. Tailors cut the hem off, shorten the legs, and stitch the original hem piece back on. It creates an awkward, unnecessary seam above the hemline—and exists only because they can’t sew cleanly through multiple layers of denim.

What most people don’t realize is this: the wear, twist, and fade of the original hem naturally returns after one or two washes. With the right thread, tension, and stitch, the new hem will age just like the original—without tricks.

T-Shirts Are No Different

If you’ve ever had a T-shirt hem curl, stiffen, or lose stretch after a tailoring job, chances are it was sewn with the wrong machine. Most shops don’t have a coverstitch machine—the industrial standard for hemming knits.

That’s why T-shirt hemming is part of our campaign too. Because tailoring knitwear also requires precision equipment. A proper hem on a tee should stretch, flex, and sit flat—just like it did before. And that takes the right tools.

Tailoring That’s Built for the Way People Live Now

The other part of this campaign is accessibility. People often ask, “Do I have to be in New York to use your services?” The answer is no. You don’t even have to leave home.

We’ve built our system so anyone in the U.S. can get professional denim and knitwear tailoring.

- You order online

- Using 2-way shipping, we email you a shipping label

- You send your garments to us

- We tailor them and ship them back

We like to say: if you can order a pizza online, you can order tailoring services from us. Just like choosing your toppings, crust style, and sides, our ordering pages walk you through clear dropdown menus to select exactly what you need—whether it’s hemming, tapering, waistband adjustments, or more.

And if you come across a term you’re unfamiliar with—like “inseam type” or “bar tack”—there’s likely a link right there to a help article, video, or visual example that breaks it down. We’ve built our platform to be intuitive, but we also understand that not everyone speaks denim. That’s why the information is always within reach.

Still have questions? Call us during business hours and you’ll speak to a real person—not an automated phone maze, robo-operator, or AI gatekeeper. Just denim people who know exactly what you’re talking about—and what your jeans need.

Putting Denim Tailoring Where People Can See It

These subway ads are the first step in a year-long marketing effort to bring denim tailoring out of the shadows. Until now, most people have either accepted poor alterations—or never even knew there was a better option.

So if you’re walking past the Bedford Avenue Station or through Manhattan along the L line, and you spot our billboard, know that it’s more than an ad. It’s a message:

There’s a better way to tailor jeans.

There’s a better way to crop your tees.

And you don’t need to be in New York to get it done right.