The first brand in our new lineup was TCB Jeans, a company out of Kojima, Japan that builds its reputation on craftsmanship, historical research, and dedication to the original spirit of American denim.

Read More →

There are two meanings when it comes to “tapered” as related to jeans, pants, and other garments designed to wear over the legs.

- Related to alterations or tailoring: The term “tapered jeans” and “tapered pants” refer to garment bottoms worn over the legs that have been altered to narrow the shape of the legs.

- Related to the design or style of a garment: It’s a jean or pant with a leg that narrows dramatically from the knee to the leg opening. Tapered clothing should not be confused with slim-fit or other jeans and pants with legs that gradually decrease in size from the knee to the leg opening.

Example of use (related to alterations): I had my jeans tapered because the legs were too baggy.

Example of use (related to design or style): I bought tapered jeans because I wanted the leg opening to be small enough that the hem wouldn’t cover my shoes.

You might be interested in

Most people simply don’t realize that tailoring jeans or knitwear is a specialized service. It’s not something every tailor does

You may have tried learning through YouTube or social media videos—but when you’re serious about mastering a craft, you quickly

If you’ve ever typed how to take in the waist of jeans into Google, you’ve probably seen a lot of

The first brand in our new lineup was TCB Jeans, a company out of Kojima, Japan that builds its reputation

Knee stretch marks are more common on skinny and slim jeans because of the way the fabric stretches when worn and the stress that comes from bending your knees. When it comes to jeans with a looser fit around the knees, the effect will be minimal to nonexistent.

The effects of stretching start from the center back of the knees as honeycombs that extend over the seams to the front. Just beyond the seams, the stretch marks quickly lose their height, depth, and color as they fade into the knees.

You might be interested in

You may have tried learning through YouTube or social media videos—but when you’re serious about mastering a craft, you quickly

If you’ve ever typed how to take in the waist of jeans into Google, you’ve probably seen a lot of

The first brand in our new lineup was TCB Jeans, a company out of Kojima, Japan that builds its reputation

The leg opening measurement is a critical factor in how your jeans fit over your shoes and shape your overall

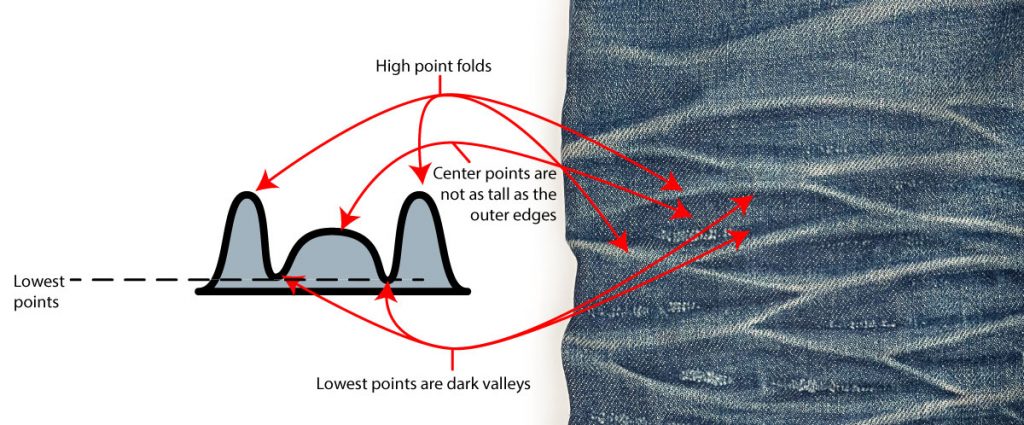

Looking at the images above, it’s easy to see why you don’t need to be a denim guru to see why some individuals prefer to let their jeans fade naturally over time from the raw denim state rather than buying jeans that have been artificially aged through manufactured washing processes. The details and three-dimensional texture that come from time and natural wear are too complicated for the fast industrial washing process to recreate.

Summary

Denim honeycombs are made from compression and decompression at the back of the knees. When denim begins stiff, such as raw denim, the initial breaking points in the bends become the points of least resistance, resulting in repeated bends and well-defined folds.

Denim honeycombs are so named due to their striking resemblance to honeycombs. They are formed as a result of compression and decompression at the back of the knees. When denim begins stiff, such as raw denim, the initial breaking points in the bends become the points of least resistance, resulting in repeated bends and well-defined folds.

The highest points, like whiskers, undergo the most abrasion and hence lighten the most in color. The lower points remain darker, resulting in transitional fades between them.

You might be interested in

You may have tried learning through YouTube or social media videos—but when you’re serious about mastering a craft, you quickly

If you’ve ever typed how to take in the waist of jeans into Google, you’ve probably seen a lot of

The first brand in our new lineup was TCB Jeans, a company out of Kojima, Japan that builds its reputation

The leg opening measurement is a critical factor in how your jeans fit over your shoes and shape your overall

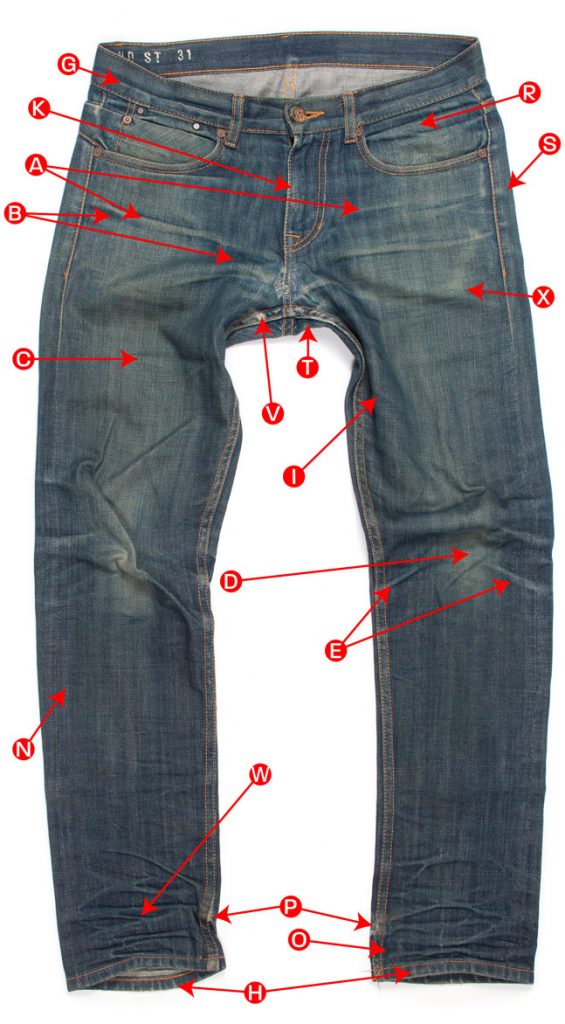

As a denim designer, I researched the causes and consequences of denim fading like a scientist to aggressively imitate real-world denim aging in my pre-washed jeans designs. This guide is a great tool for understanding how to create the various fading effects that develop on jeans for those looking for tips on “how to fade jeans” naturally. Here’s what I discovered.

A – Whiskers

Whiskers, also known as mustaches, hige, crease lines, are lines that naturally form along folds in the front hip area of jeans as a result of repetitive stretching and movement. With abrasion, the highest points of the folds fade the lightest in color. The denim fabric holds more color and appears darker as you move down the folds.

B – Whisker Texture

Highs and lows form around whiskers, giving them a texture. When denim is stretched and pulled around the hips at the front rise, dark patches form. There are lighter areas (whisker lines) where the color has been worn off by friction.

C – Thigh Fading

The indigo color in the denim yarns fades because of abrasion against the thighs. When we sit, our arms and hands rest on our thighs, which wears away the color.

D – Knee Fading

The knees are one of the most stressed areas in jeans. If you frequently work or perform tasks on your knees, they will rapidly fade.

E – Knee Stretch Marks

Knee stretching will happen along with fading. This is particularly noticeable in jeans made of raw denim that has naturally aged. Lines with high and low basins protrude like whiskers in the knee flexion direction.

F – Seat Fading

Each time a person sits in a pair of jeans, the seat fades slightly. This is the result of a small amount of color rubbing off the yarns, which lightens the overall appearance.

G – Waistband Fading

Belt-related friction is the most common cause of waistband wear and tear. Randomly, the seam line within the waistline becomes visible.

H – Hem Fading

Fading or destruction at the hem can occur in a variety of ways. Rope-like twisting fade lines will appear at the high points if the hem is sewn unevenly at the in-and-out seams. Shredding or fraying can occur over time when jeans are too long and drag on the ground.

I – Chevrons

Chevrons are the fade lines that appear on the inner thighs of jeans just above the inseam. Walking, squatting, and sitting can all stretch the inseam. Friction on the high points of the stretch lines rubs away the yarn color, resulting in chevrons.

J – Rear Knee Honeycombs

One of the most sought-after fadings among raw denim fans, the rear knee honeycombs, are the result of months or even years of natural aging. When fabric bends and collapses on itself on the back side of the knees, the high points fade from abrasion while the low points remain darker, creating a honeycomb appearance.

K – Fly Abrasion

The fading around the fly is a continuation of the whiskers and adheres to the same principles. The high points are abraded the most, while the lower areas remain darker. It’s worth noting that zippers and button-fly jeans fade in different ways. The spaces between the buttons on button-fly jeans facilitate the formation of high and low fading horizontally, which extends into the hips across the front rise, resulting in more detailed fade patterns. There are typically more vertical abrasion highlights on the zipper fly, which does not bend as easily.

L – Seat Seam Abrasion

On jeans, the seat and back pocket seams are high points that take a lot of abuse every time the wearer sits. The high points and edges of jeans deteriorate and fade the fastest in time.

M – Back Pocket / Wallet Fades

If you carry items in your rear pockets on a regular basis, such as wallets or phones, the color in the high spots of the denim will fade faster due to abrasion each time you sit on them.

N – Outseam Lines / Train Tracks

Due to their resemblance to railway tracks, the two faded lines that develop on either side of the outseams of jeans manufactured with selvedge edges or overlock seams that have been pressed open on the inside of the jeans are frequently referred to as “train tracks.” If the outside seams of the jeans are sewn together, these lines won’t show up.

O – Cuff Lines / Roll Creases

Depending on how you wear your long, rolled, or cuffed jeans, lines will appear differently. The bottom of the denim may become ragged or frayed if you roll them such that the length hits the ground. If the roll or cuff is high, a dark line may appear on the face of the denim from a lack of abrasion.

P – Inseam Abrasion

Because the inseam is a high point on jeans, they tend to wear faster from abrasion, especially in the crotch and at the hem, where there is a lot of friction. These highlighted high spots often get whiter and brighter with age than other regions of the jeans.

Q – Belt Loop Fading

Belt loops, like other elevated places, suffer a lot of abrasion damage. With aging, they wind up with fraying plus having some of the brighter white portions, particularly at the ends and center points.

R – Front Pocket Whiskers & Crease Lines

The aging process here is comparable to that of the whiskers around the thigh. The denim stretches as a result of sitting and walking, and the waistband compression exaggerates the peaks and valleys inside the hand pockets just below the waistline. The coin pocket suffers from wear and develops highlights on the coin pocket side.

S – Hip Whiskers

Hip whiskers extend from the middle of the front rise and wrap around the hip outseams before fading out on the back side, just past the seamline.

T – Crotch Fading / Blowout

Due to the continual rubbing of the fabric against fabric between the legs, the crotch of jeans sustains the most wear and tear. Complete crotch blowouts that result in crotch holes are influenced by the wearer’s body type, how high or low they wear their jeans, and the denim’s thickness (lighter weight textiles may blowout more quickly than heavy).

U – Seat Lines / Rear Crotch Whiskers

Because of the lower resistance and compression at the location where the fabric folds, subtle whiskers can emerge just below the back pockets. These lines originate from the crotch’s center point stress area.

V – Crotch Seam Damage

During normal wear, the elevated seams in the crotch receive the most abrasion from all of the rubbing inside the crotch and frequently acquire frayed edges, high contrast, and even tears.

W – Denim Stacks

Stacks on jeans occur when the length of the jeans is so long that the denim fabric buckles and crinkles, or stacks on top of itself. Over time, honeycombs form above the hem. The longer the excess length is at the inseam, the more and higher the stack forms over the leg opening.

X – Pocket Bag Fading

Abrasions on the thighs can cause fading over the pocket bag. The pocket’s outline, or high points, or items that stay in the pocket for an extended period of time can form outlines of their shapes.

You might be interested in

You may have tried learning through YouTube or social media videos—but when you’re serious about mastering a craft, you quickly

If you’ve ever typed how to take in the waist of jeans into Google, you’ve probably seen a lot of

The first brand in our new lineup was TCB Jeans, a company out of Kojima, Japan that builds its reputation

The leg opening measurement is a critical factor in how your jeans fit over your shoes and shape your overall

An original hem also called a European hem, or euro hem is an alteration method where the goal is to shorten jeans and pants without losing the original manufactured hem. This alteration technique is a perceived value on garments with pre-washed or aged hem edges to those who do not want to lose the look.

This method of hemming is preferred among sewers with home and common-duty industrial machines. It allows them to dodge sewing through multiple layers of denim fabric required in traditional jeans hemming. Besides preserving tatter hem edges, some techniques preserve the manufacturer’s stitching above the hem, which is too thick for home machines, and usually not stocked at most dressmakers and tailoring shops.

The alteration method above has a clean inside construction but its construction style causes the hem to be stiff and ring-shaped. The customer who sent this pair in removal and re-hemming complained it was annoying to wear.

Denim enthusiasts and those generally knowledgable about jeans avoid original hem alterations. It is an alteration procedure typically advocated by DIY diehards and non-denim experts because it is generally easier for their equipment to handle. The tailor’s selling point of the process is the preservation of the store-bought hem. Void in the conversation is the annoying inside bulk around the ankles, goofy seamline, or stiff ring-like shape of the cleaner sewn version of the alteration – and the fact that the aged look of the hem will naturally come back through frequent washing and/or wear.

Denim jeans and like-constructed pants are predominantly sewn with chain stitching at the hem and heavy threads that can withstand harsh washing, not typical in other garments. However, even denim lovers more knowledgeable than the average mom about jeans and workwear can get talked into an original hem alteration. Either that or don’t ask the right questions in choosing a hemming service. Have a look at a few examples of jeans and pants sent to us in need of rescuing.

Iron Heart fans should be warned, that the photo below could be extremely upsetting.

This is a prime example of bad tailoring. These rather expensive and high-quality jeans were tapered from the outseams, destroying the selvedge. Not to go far enough, the tailor topped them top off with an original hem alteration. Here there is no reason to save an aged-looking hem edge. The obvious reason for using this hemming technique is the lack of equipment able to sew through the heavy denim typically found in Iron Hearts jeans.

You might be interested in

You may have tried learning through YouTube or social media videos—but when you’re serious about mastering a craft, you quickly

If you’ve ever typed how to take in the waist of jeans into Google, you’ve probably seen a lot of

The first brand in our new lineup was TCB Jeans, a company out of Kojima, Japan that builds its reputation

The leg opening measurement is a critical factor in how your jeans fit over your shoes and shape your overall

Chain stitching is a type of stitch produced by a sewing or embroidery machine. The name chain stitch comes from its looped chain-link-like appearance. In sewing, a chain stitch has a single stitch line on the top side and a looped chain-like stitch on the bottom side.

Single, double, and triple-needle chain stitching is popular in denim clothing and similarly constructed garments. It is usually found on high-stress seams which often incur stretchings such as the center seat seams, yokes, panel seams, inseams, and waistbands. The triple-needle is more often used in workwear.

Tension in the stitch pulls the fabric into a slight pucker, allowing a bit of stretching. A favorite in garment manufacturing because it provides a strong durable stitch that can easily be undone if needed. The tension creates a decorative puckering effect which is especially visible on denim seams and hems, as the fabric shows signs of aging, washing, and wear.

What is hemming?

Hemming is the sewing process of shortening the length or finishing the bottom edge on a pair of jeans or pants. Hemming uses a method of double folding into itself the raw fabric edge of the leg openings to make a clean smooth edge.

What is chain stitch hemming?

Chain stitch hemming is when a pair of jeans or pants are hemmed with a chain stitch sewing machine. The hem of most jeans is traditionally sewn with chain stitching about 1/2″ above the bottom edge. Some makers choose to make the height of the hem taller or shorter as a choice of design aesthetic. The below photo is an example of a chain-stitched hem with a traditional-sized hem.

Why are some jeans made with a regular stitch at the hem?

We see jeans without chain stitching predominantly in the work of novice denim brands or designers inexperienced in the category of denim. However, being a neophyte is not the rule as seen on the below hem of Levi’s jeans. Even the biggest most celebrated brands sometimes use factories accustomed to producing low-end / discount denim and commonly disregard chain stitching if not a design decision.

To be clear, we don’t know why any brand would purposely choose to use a regular stitch at the hem, especially if they are well-established denim brands, however, some are known to do so. Take A.P.C. for example, which is a major French brand that has a generally well-educated denim customer base and has been pretty successful in making jeans for a long time. They purposely choose to go with a hem fold that is larger than most jeans, plus use a single needle stitch (trouser styled). This is obviously an aesthetic choice.

That said, customers that send us A.P.C. jeans for hemming or tapering, almost always request traditional chain stitching and hem size. Very rarely do our alteration customers request trouser-styled hem construction, which may be an insight into the thinking of U.S. enthusiasts.

Video of Chain Stitch Hemming in Action

You might be interested in

TCB Jeans crafts history into every stitch, reviving iconic denim like the 1966 Levi’s 501 and the 1955 Levi’s 701

Is it called selvedge or selvage and what is it? We explain.

This video, which we posted on Instagram and TikTok, walks you quickly through our chain stitch hemming procedure.

What are they, and why are they sewn over the chain-stitched hem line on some jeans?